FACC develops and manufactures composite structures for Ariane 6 launch vehicle

Astris kick stage main structure will be characterized by high strength and the use of ultralight carbon fiber material, with first delivery scheduled for October 2022.

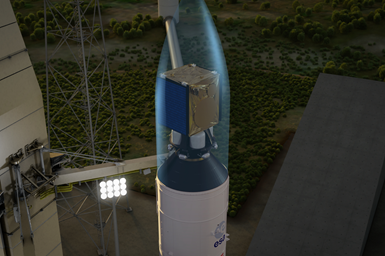

Ariane 6 kick stage. Photo Credit, all images: FACC AG

In an effort to use its composites technologies to tap into end markets outside of its core aerospace business, FACC AG (Ried im Innkreis, Austria) has secured its first project under its New Space business segment, with an order from the ArianeGroup (Paris, France) to develop and manufacture the Astris kick stage main structure for the Ariane 6 family of launch vehicles.

“By awarding us a contract to participate in the Ariane 6 rocket, the ArianeGroup has placed its trust in us to help shape the new generation of European launch vehicles as a development and manufacturing partner,” notes Robert Machtlinger, CEO of FACC. “For us, space is an important future topic, which we have defined as a new business field in our 2030 corporate strategy. This is an area where we can make valuable use of our FACC composite technologies, which we have been developing for the aviation industry over the past decades. Our goal is to apply our lightweight construction expertise and state-of-the-art manufacturing facilities to provide a carbon fiber solution for the load-bearing structure of Ariane 6 kick stage that will reduce weight and enable use for commercial space transportation through efficient series production.”

The ArianeGroup is a leading enterprise in the field of space transportation. With its new launch vehicle, the company aims to offer maximum flexibility to its customers in institutional and commercial markets. Ariane 6 is a program of the European Space Agency (ESA), and is designed to provide independent access to space for a wide range of missions.

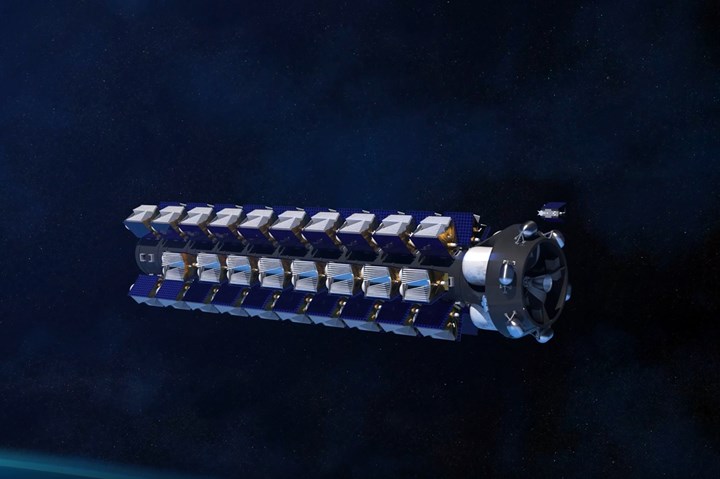

The kick stage main structure, which will be developed and produced by FACC, is the load-bearing structure of an additional optional stage which is designed to expand the Ariane 6’s mission range and make the rocket more versatile in terms of the types of payloads it could carry. The component is characterized by high strength and the use of ultralight carbon fiber materials; it carries, in addition to the actual payload, four fuel tanks, the newly developed Berta engine and state-of-the-art flight electronics into higher spheres. In addition, the use of carbon fiber for the launch vehicle’s rocket stage is also under development.

The first delivery is scheduled to arrive in Bremen, Germany, in October 2022. There, the kick stage will undergo further tests for a potential first mission, the ESA’s Hera mission, which is to demonstrate planetary asteroid defense technologies. The goal of Hera is to test the extent to which an asteroid can be deflected from its trajectory by means of two comets passing by Earth.

Overall, FACC’s contribution brings the company a step closer to looking beyond existing horizons and establishing itself as an innovator in multiple fields.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.