Firefly Aerospace completes composite Blue Ghost lunar lander

First of two lunar missions under NASA’s CLPS initiative will launch in 2024 and conduct diverse technology demonstrations and scientific investigations on the moon’s surface.

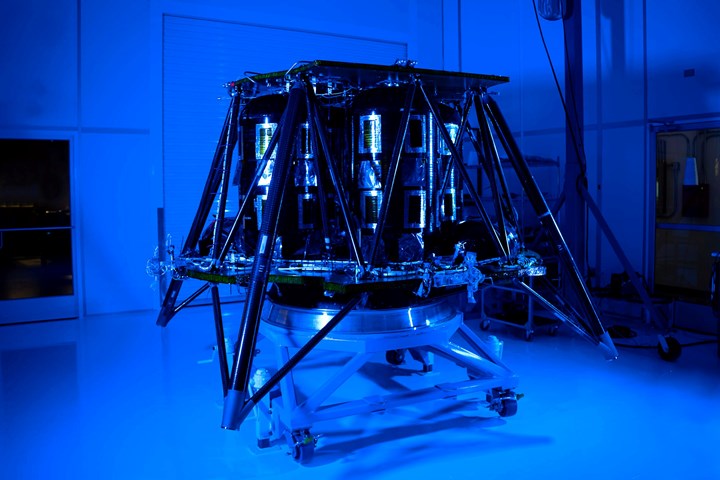

Firefly Aerospace (Cedar Park, Texas, U.S.) has completed the development and assembly of its Blue Ghost lander structure and fluid systems, a critical milestone for Firefly’s first lunar mission slated to land on the moon in 2024 as part of NASA’s (Washington, D.C., U.S.) Commercial Lunar Payload Services (CLPS) initiative. This mission is one of three task orders Firefly has won under NASA CLPS, accounting for more than $230 million in awards.

Firefly’s ability to rapidly design, build and test the Blue Ghost lunar lander can be credited to its in-house manufacturing and test facilities. The lander’s core components, including the panels, struts, legs, harnesses, avionics, batteries and thrusters, were designed and built in-house using Firefly’s flight-proven carbon fiber used in the company’s Alpha and Elytra orbital vehicles, providing lightweight, stronger-than-metal structures (read “The Alpha launch vehicle: Designing performance in, cost out”).

The team conducted extensive qualification testing on the assembled Blue Ghost structure and each component to ensure the lander will withstand all launch, transit and landing load cases. This included conducting more than 100 drop tests on multiple surfaces, including sand, lunar simulant and concrete; testing hazard avoidance and the terrain navigation system’s ability to scan, measure and adjust; and partnering with Northrop Grumman (Denver, Colo., U.S.) to conduct full vibration and shake testing to ensure the design meets or exceeds spaceflight requirements.

“Firefly is able to have more control over our mission schedules and less dependency on the supply chain thanks to our in-house manufacturing capabilities and facilities that accommodate the development of multiple landers,” Jana Spruce, vice president of spacecraft at Firefly Aerospace, says. “Our vertically integrated approach with shared components across our vehicles further enables scaled efficiencies, lower costs and quality assurance that we pass on to our customers.”

Blue Ghost Mission 1 will carry commercial and government payloads, including 10 NASA-sponsored instruments, to Mare Crisium on the moon’s near side. The payloads support NASA’s goal to build a sustainable lunar presence by conducting several first-of-its-kind demonstrations, including testing regolith sample collection, global navigation satellite system abilities, radiation tolerant computing and lunar dust mitigation. Nearly all of the payloads have been processed at Firefly’s facility and successfully passed fit checks and functional checkouts on the lander.

The next major milestones for Blue Ghost Mission 1 include payload integration followed by environmental testing before the mission launches in 2024. Concurrently, Firefly is ramping up for its second lunar mission, Blue Ghost Mission 2, that will first deploy a satellite to lunar orbit and then deliver multiple payloads to the far side of the moon in 2026. Mission 2 has remaining capacity to offer payload delivery and orbital services for commercial customers.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Sinonus launches energy-storing carbon fiber

Swedish deep-tech startup Sinonus is launching an energy-storing composite material to produce efficient structural batteries, IoT devices, drones, computers, larger vehicles and airplanes.

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.