CFM RISE program targets composites, additive manufacturing and hybrid electric

GE Aviation, Safran program targets more than 20% lower emissions, 100% compatibility with sustainable and hydrogen fuels, with a technology roadmap detailing CMC, composite fan blades and more.

Share

GE Aviation (Cincinnati, Ohio, U.S.) and Safran S.A. (Paris, France) have launched a bold technology development program targeting more than 20% lower fuel consumption and CO2 emissions compared to today’s engines. The CFM RISE (Revolutionary Innovation for Sustainable Engines) program will reportedly demonstrate and mature a range of new, disruptive technologies for future engines that could enter service by the mid-2030s. While no specific mention of composites has been made, the joint team’s comprehensive technology roadmap does include composite fan blades, heat-resistant metal alloys and ceramic matrix composites (CMC), suggesting that composites will be critical to the engines that are developed.

The companies also signed an agreement extending the CFM International 50/50 partnership to the year 2050, declaring an intent to lead the way for more sustainable aviation in line with the industry’s commitment to halve CO2 emissions by 2050.

“The relationship between GE and Safran today is the strongest it has ever been,” says John Slattery, president and CEO of GE Aviation. “Together, through the RISE technology demonstration program, we are reinventing the future of flight, bringing an advanced suite of revolutionary technologies to market that will take the next generation of single-aisle aircraft to a new level of fuel efficiency and reduced emissions. We fully embrace the sustainability imperative. As we have always done in the past, we will deliver for the future.”

The RISE program includes more than 300 separate component, module and full engine builds.

“Our industry is in the midst of the most challenging times we have ever faced,” adds Olivier Andriès, CEO of Safran. “We have to act now to accelerate our efforts to reduce our impact on the environment. Since the early 1970s, breakthrough engine efficiency and reliability have been the hallmark of our historic partnership and our LEAP engine already reduces emissions by 15% compared to previous generation engines. Through the extension of our CFM partnership to 2050, we are reaffirming our commitment to work together as technology leaders to help our industry meet the urgent climate challenges.”

Technologies matured as part of the RISE Program will reportedly serve as the foundation for the next-generation CFM engine that could be available by the mid-2030s. In addition to reducing fuel consumption and CO2 emissions by more than 20%, program goals will also ensure 100% compatibility with alternative energy sources such as sustainable aviation fuels and hydrogen.

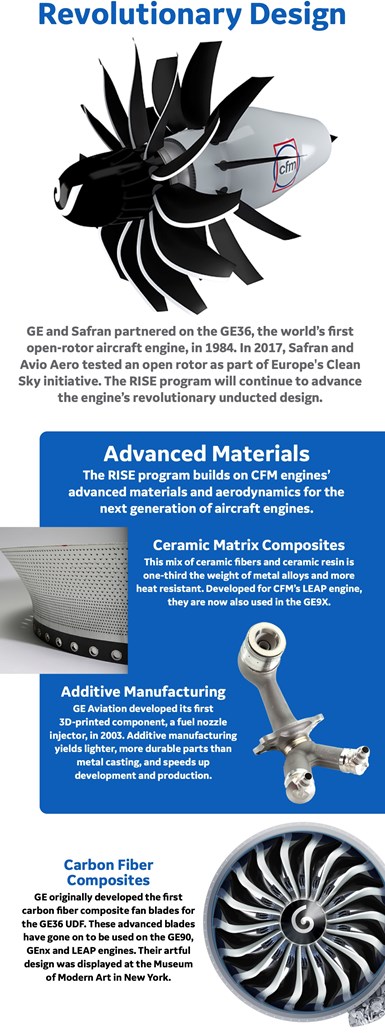

Central to the program is state-of-the-art propulsive efficiency for the engine, including developing an open fan architecture. Partners notes that this is a key enabler to achieving significantly improved fuel efficiency while delivering the same speed and cabin experience as current single-aisle aircraft. The program will also use hybrid-electric capability to optimize engine efficiency while enabling electrification of many aircraft systems.

Infograph Credit: GE Reports.

The program is being led by a joint GE/Safran engineering team that has laid out a comprehensive technology roadmap including composite fan blades, heat-resistant metal alloys, ceramic matrix composites (CMC) hybrid-electric capability and additive manufacturing (AM). The RISE program includes more than 300 separate component, module and full engine builds. A demonstrator engine is scheduled to begin testing at GE and Safran facilities around the middle of this decade and flight test soon thereafter.

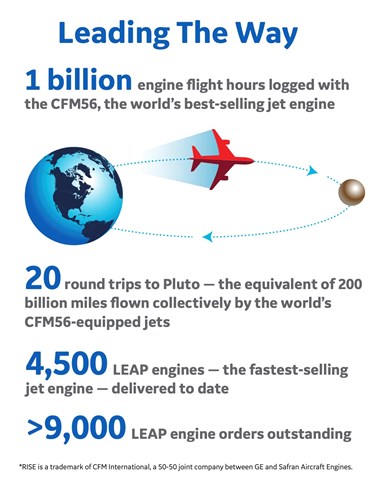

The original 1974 framework agreement creating CFM International as a 50/50 joint venture between the two aircraft engine manufacturers redefined international cooperation and helped change the course of commercial aviation. The partnership was renewed in 2008 for the launch of the LEAP program (see “LEAP backlog spurs composites production expansion”). Today, CFM is said to be the world’s leading supplier of commercial aircraft engines with a product line that serves as the industry benchmark for efficiency, reliability and low overall cost of ownership. More than 35,000 CFM engines have been delivered to more than 600 operators around the globe, accumulating more than one billion flight hours.

Visit Aviation Week, GE Avation and Airframer’s CFM RISE announcement for additional details.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More