GE combines rotating detonation, ramjet in hypersonic engine program

New architecture, incorporating high-temperature CMC and electronics, could power efficient hypersonic vehicles with longer range that exceeds Mach 5.

GE Aerospace (Cincinnati, Ohio, U.S.) has lifted the curtain on its comprehensive hypersonics program at the company’s research center in Niskayuna, New York, demonstrating what is believed to be the world’s first hypersonic dual-mode ramjet (DMRJ) rig test with rotating detonation combustion (RDC) in a supersonic flow stream. This could help enable high-speed, long-range flight with increased efficiency. The milestone and overall portfolio of programs position GE Aerospace to pursue multiple opportunities in the hypersonic sector as it prepares to launch as a standalone company in Q2 2024.

The successful high-speed propulsion DMRJ demonstration is part of a comprehensive portfolio of technology programs GE Aerospace is developing and scaling to advance hypersonic capabilities, including high-temperature materials and high-temperature electronics. These technologies are the product of more than a decade’s worth of direct hypersonic-related efforts advanced by GE Aerospace Research and several decades of developments for its GE Aerospace engine business in key areas like high-temperature ceramic matrix composites (CMC), silicon carbide power electronics, additive technologies and advanced thermal management.

“As the aerospace sector sets its sight on the future of hypersonics, GE Aerospace is well positioned with the right capabilities, experience and scale to be a leader in driving new developments for our customers,” says Amy Gowder, president and CEO of GE Aerospace, defense and systems. “The successful demonstration of a DMRJ with RDC is an outgrowth of our 10-plus years of RDC work, including the strategic acquisition of Innoveering that has brought leading technologies and experience in hypersonic propulsion and ramjets.”

A typical air-breathing DMRJ propulsion system can only begin operating when the vehicle achieves supersonic speeds of greater than Mach 3. GE Aerospace engineers are working on a rotating detonation-enabled dual mode ramjet that is capable of operating at lower Mach numbers, enabling the flight vehicle to operate more efficiently and achieve longer range.

The acquisition of Innoveering in 2022 gave GE Aerospace dual mode ramjet engine capabilities that were rapidly augmented with GE Aerospace Research’s decades-long work in RDC and several decades of GE Aerospace experience in high Mach research and engine development programs. RDC enables higher thrust generation more efficiently, at an overall smaller engine size and weight, by combusting the fuel through detonation waves instead of a standard combustion system that powers traditional jet engines today.

Mark Rettig, vice president and general manager, Edison Works business and technology development, GE Aerospace, says that it took just 12 months from start to finish for the DMRJ with RDC demonstration. The team is on track with its goal to demonstrate a full DMRJ with RDC at scale next year.

Related Content

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

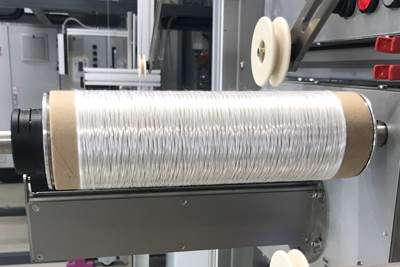

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Stratolaunch TA-1 test vehicle completes captive carry flight

The flight was the 12th for the company’s launch platform Roc and the first carrying the Talon-A testbed vehicle with live propellant, in preparation for its first powered hypersonic flight.

Read MoreGE Aerospace to open Dayton manufacturing site

Co-located Beavercreek facility for aeroengine production ramp-up is expected to simplify GE’s operations and help better serve customers.

Read MoreRATH works with InVECOF project to mature oxide fiber production in Europe for CMC

Producer of Altra ceramic staple fibers aims to scale up continuous Ox fibers to compete with Nextel 610 and 720, and with its partners, offer improved fibers with creep resistance for higher temperature CMC applications.

Read More