GE, Fraunhofer IGCV, Voxeljet to develop the world’s largest 3D printer for offshore wind applications

The partnership will streamline the production of key components of GE’s Haliade-X offshore wind turbine with the advance casting cell (ACC) sand binder jetting 3D printer.

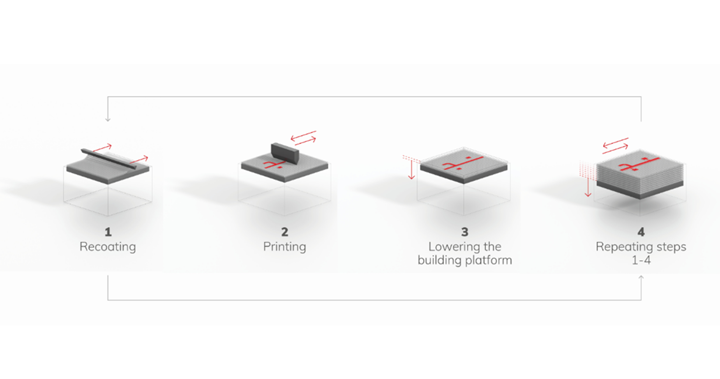

The basic binder jetting process is defined by spreading a layer of particle material onto a building platform. Subsequently a print head applies a binder into the powder bed where the part is to be printed. Then, a new layer of material is applied and the process repeats until the final part or mold is printed. Photo Credit, all images: Voxeljet

GE Renewable Energy (Paris, France), Fraunhofer Institute for Casting, Composite and Processing Technology IGCV (Garching, Germany) and Voxeljet AG (Friedberg, Germany) have partnered to develop the world’s largest 3D printer for offshore wind applications. The goal of the partnership is to streamline the production of key components of GE’s Haliade-X offshore wind turbine with the advance casting cell (ACC) 3D printer, which is currently under development.

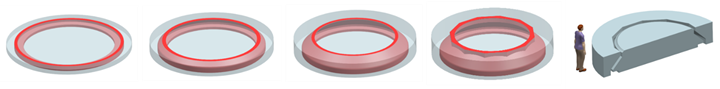

The ACC printer will be designed to print molds for key components of wind turbines, with sizes up 9.5 meters in diameter and 30-60 tons in weight.

The ACC is capable of printing molds to cast components for the nacelle of the GE Haliade-X that can each weigh more than 60 metric tons, reportedly reducing the time it takes to produce this pattern and mold from ten weeks or more to just two weeks. The modular 3D printing process, which is based on Voxeljet’s binder-jetting technology, can be configured to print molds for castings up to 9.5 meters in diameter and 60-plus tons in weight. In addition, the use of the 3D printer is expected to reduce the product’s carbon footprint by eliminating the need to transport the large parts from a central manufacturing location. The partners expect to launch the project during the third quarter of 2021 with initial printer trials starting during the first quarter of 2022.

Juan Pablo Cilia, senior additive design engineer at GE Renewable Energy, says, “The 3D-printed molds will bring many benefits, including improved casting quality through improved surface finish, part accuracy and consistency. Furthermore, sand binder jet molds or additive molds provide cost savings by reducing machining time and other material costs due to optimized design.”

Fraunhofer IGCV is responsible for casting and materials technology issues as well as digital process monitoring. The team expects to significantly improve the environmental footprint of processes involved in producing the Haliade-X type wind turbines.

Christian Traeger, director of marketing and sales at Voxeljet, says, “With the ACC, we aim to print a significantly reduced number of parts for the full set. The mold can be optimized in terms of functionality and material consumption. This optimization makes completely new casting designs possible that can further enhance the efficiency of the turbines.”The International Energy Agency (Paris, France) has projected that global offshore wind capacity will increase 15-fold by 2040, becoming a $1 trillion industry due to falling costs, supportive government policies and technological progress. GE Renewable Energy will supply its Haliade-X turbine for 5.7 GW worth of projects in Europe and the U.S. The company is a member of the Offshore Wind Industry Council (OWIC) and, as part of that, supports various initiatives that aim at increasing the production of sustainable wind energy.

Related Content

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePolar Technology develops innovative solutions for hydrogen storage

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreRead Next

GE to supply 14-MW Haliade-X wind turbines to Dogger Bank Wind Farm

Confirmed as the supplier for all three of the U.K. offshore wind farm’s phases, GE will begin installing its most powerful, 14-MW turbine variants in 2025.

Read MoreGE to test Haliade-X 12-MW wind turbine prototype

The Haliade-X 12 MW prototype will be installed in Rotterdam, The Netherlands where data will be collected with the aim of obtaining Type Certification.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More