Georgia Tech leads effort to tackle the composite and hybrid materials challenge

New National Science Foundation (NSF) center combines industry and academia, uses analytics, AI to modernize how manufacturers repair composites.

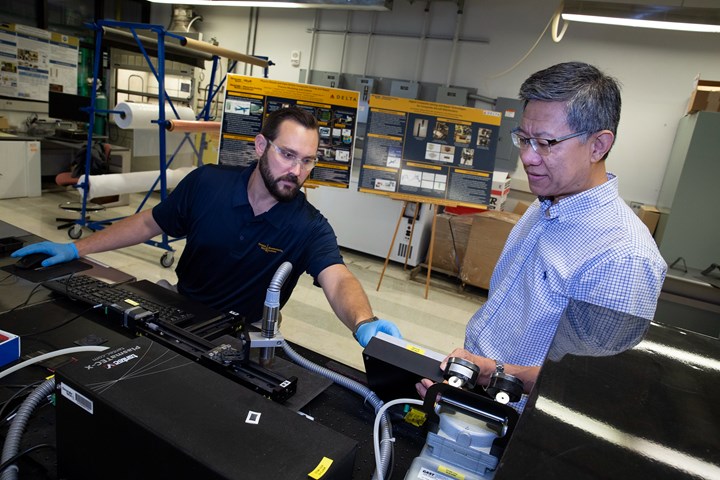

Jarod Weber, CHMI project manager, and Chuck Zhang, CHMI director, perform and monitor plasma treatment surfaces of composite panels before they are bonded in GTMI’s Composite Joining and Repair (CJAR) Lab. Photo Credit: Candler Hobbs, Georgia Tech

Based at the Georgia Institute of Technology (Atlanta), the Center for Composite and Hybrid Materials Interfacing (CHMI) intends to dramatically improve how composite and hybrid structures are joined and repaired. The Center is one of four active National Science Foundation (NSF) Industry/University Cooperative Research Centers (IUCRCs) at Georgia Tech. Funded for five years with an NSF IUCRC grant, the Center will reportedly work closely with an industry consortium of leading manufacturers and government organizations that will underwrite research projects.

Housed in the Georgia Tech Manufacturing Institute (GTMI), the Center incorporates three university research teams from Georgia Tech, Oakland University (Detroit, Mich., U.S.) and University of Tennessee, Knoxville (UT). Each research and development partner are said to bring decades of composite and hybrid materials research focus in specific industries: Georgia Tech in aerospace, Oakland University in automotive composite systems and UT in infrastructure and medical devices.

“The study of the interface between composite, metallic and other electronic materials is really the future of manufacturing,” says Ben Wang, executive director of GTMI. “The Center amplifies the thought leadership of Georgia Tech advancement in composites. It also puts us in the nexus of three areas: advanced manufacturing, innovative materials and data analytics.”

Center director Chuck Zhang, Harold E. Smalley Professor in Georgia Tech’s H. Milton Stewart School of Industrial and Systems Engineering (ISyE), will drive CHMI’s vision to transform the current labor-intensive, experience-based joining and repair practice into fast, automated and reliable processes.

“Using advanced computation, experimental, data analytics and digital techniques and tools, we hope to reduce by 50% the overall cost, cycle time and variation of these processes in the next 10 years,” Zhang says.

“This Center allows us to create a convergent platform where industry comes together with academia in both a structured and targeted way to advance manufacturing in the U.S.”

As an IUCRC, the Center expects to engage Georgia Tech and partner faculty and researchers and students, in addition to industry partners. Each university partner will rotate hosting in-person briefings with the consortium every six months, with the first meeting set for October at GTMI. According to Wang, the frequent engagement between researchers and industry partners will “help ensure a strong understanding of the challenges and possible solutions. The outcome is really a very robust research agenda.”

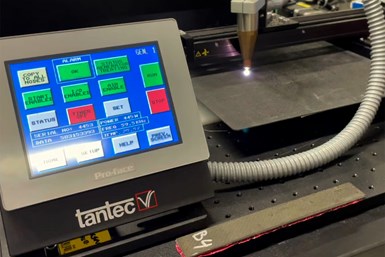

The Tantec PlasmaTec-X, optimizing the surface of a carbon fiber panel prior to the adhesive joining process. This automated system increases surface energy for composites, metals and surface coatings involved in joining and repair processes. Photo Credit: Candler Hobbs

According to Georgia Tech, the Center will solve key challenges facing industries that rely on composite materials. The university illustrates a bird striking a plane, which can damage a composite structure on the wing of the aircraft, which might then require the deployment of specialized, expensive patches — often to remote locations — training challenges with technicians and the high cost of grounding a plane. Pulling an Airbus A350 out of service for a single day, says Georgia Tech, costs an airline an estimated $100,000 or more in lost revenue. Therefore, the university believes repairing composites represents a supply chain challenge beyond one company’s capabilities to solve.

“No company can do this on their own — it’s too multidisciplinary,” says Rob Maskell, chief scientist of global composite manufacturer Solvay Materials (Brussels, Belgium and Alpharetta, Ga., U.S.). “Solving this challenge is critical to the increased adoption of composites, and I think Georgia Tech brings a lot of competencies that, when combined with Solvay’s expertise, gives us credibility.”

Solvay Materials has been involved from the beginning and is one of the Center’s eight founding consortium members. “Joining industry and academia in this Center is an essential piece on the road to the increased commercialization and adoption of composites,” Maskell says.

Maskell notes that the current manual repair process for composites could be replaced with analytics, automation and digital technologies. He also sees additive manufacturing — or 3D printing — as a future key efficiency driver.

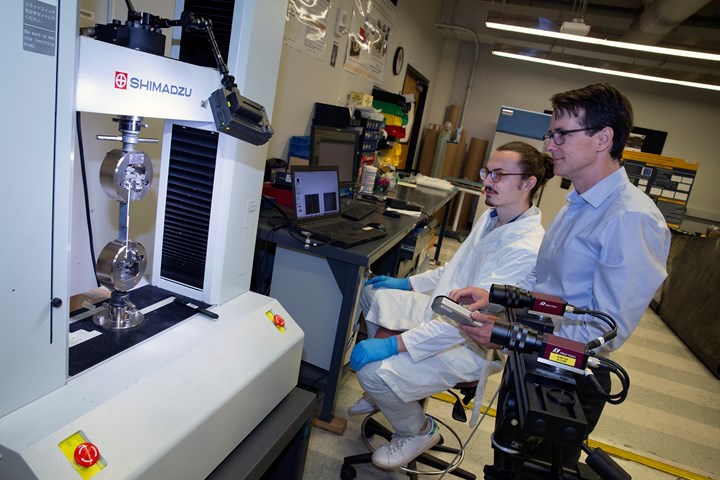

Prof. Chris Muhlstein and his graduate student, Daniel Cantrell, conduct composite joint testing with the Digital Image Correlation technique. Photo Credit: Candler Hobbs, Georgia Tech

The Center will also help support workforce development in the composite area, both to educate graduate and undergraduate students and create a funnel for future workers in the industry once they graduate. Wang says the Center will also create a technology and knowledge database of new tools for companies to use in production lines. Georgia Tech leadership sees it as a win-win for researchers and industry.

“Getting this Center approved will benefit quite a few faculty members. We have expertise in trends and applications in artificial intelligence and machine learning,” adds Edwin Romeijn, ISyE H. Milton and Carolyn J. Stewart School Chair and professor. “The Center also touches on issues of supply chain design and management, transportation and autonomous vehicles, which are big strengths of ISyE as well.”

Joining Zhang from Georgia Tech are co-principal investigators Christopher Muhlstein and Donggang Yao, both professors in the School of Materials Science and Engineering. Yao focuses on creating materials and developing material systems to make and join composites together, while Muhlstein studies the mechanical behavior of these materials. Zhang’s background in modeling, simulation and optimal design in a manufacturing setting ties it all together.

“As an engineer of composites, you need all these pieces,” explains Muhlstein, who strives to create a more predictable, reliable and high-confidence bond between the composites and the structures. “The moment that you can use the composite all the way to its limit, and do that with confidence, now you enable whole new classes of airplanes and cars — or even completely new applications.”

The CHMI launches with a well-defined technology roadmap, having benefited from earlier grant and collaborative discussions with industry partners.

According to Zhang, the concept for the Center originated in 2015, when Georgia Tech received a National Institute of Standards and Technology grant to identify top challenges and R&D needs facing aerospace companies and then develop a 10-to-15-year technology roadmap focused on research in that area. More than 50 companies and government organizations, including Boeing, Lockheed Martin, Airbus and component manufacturing suppliers were polled on their top five technology challenges, and “composite joining and repair was one of the top three technology areas cited,” Zhang recalls.

The Georgia Tech principal investigators consider the deep materials and analytics expertise at Georgia Tech a key strength of the Center. According to Muhlstein, having industry involvement ensures that “we as researchers get great problems to work on. This Center allows us to create a convergent platform where industry comes together with academia in both a structured and targeted way to advance manufacturing in the U.S.”

Related Content

Aerodynamic considerations when repairing complex composite structures

An example process gives steps and issues to consider when determining the most effective repair method for preserving the aerodynamic surface of a complex-contoured composite sandwich structure.

Read MoreComposite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreSegula Technologies initiates Z-WasTEK project for composite recycling, repair

The combined use of 3R resin and the development of digital programs will target the repair and more responsible use of carbon fiber.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More