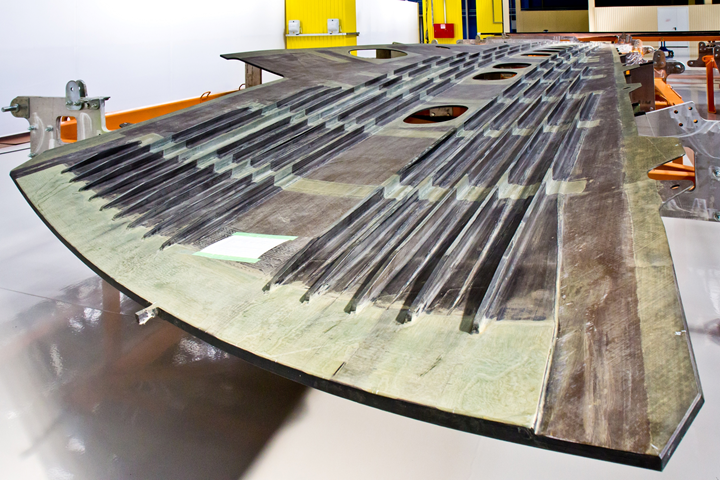

Global aerospace manufacture uses sensXPERT to shorten cycle times, meet increased rate and reduce waste

Using minimal sensors and one edge device, data from 20 production cycles was used to train machine learning models, accurately predicting outcomes in ≤50 minutes by forecasting when target degree of cure is reached.

In a recent case study presented at the SAMPE Europe Conference 2023 in Madrid, Spain, sensXPERT’s (Munich, Germany) demonstrated how its digital manufacturing development, the Digital Mold, has transformed composites manufacturing for a large global aerospace manufacturer. The system provides real-time insights into in-mold material behavior, enabling dynamic process adaptation and optimization of cycle end-times based on desired degree of cure (DoC) targets.

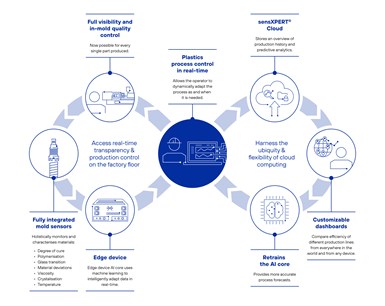

To use the Digital Mold, dielectric sensors are strategically placed within the mold, capable of withstanding extreme temperatures and pressures, and an edge device is positioned outside the mold to collect data from the sensors. The edge device interface (Web App) visualizes active processes and employs machine learning and predictive algorithms to determine the optimal curing point in real time. Data collected during production cycles is transferred to the sensXPERT Digital Cloud Service, where it’s stored, visualized and compared with historical process data to assess various quality indicators.

The outcome? Manufacturers gain full transparency in molding cycles, can pinpoint optimal curing points and detect potential in-situ process or material behavior deviations. With quality assurance testing now performed within the mold, manufacturers experience increased process stability and reduced final part defects.

According to this recent case study, data from 20 production cycles was collected and used to train a machine learning model, specifically tailored to the aviation manufacturer’s process. Using dielectric sensors, sensXPERT accurately predicted the outcome of the cycle in as little as 50 minutes, for real-time process adaptation.

Additional benefits to implementing sensXPERT’s solution includes cycle time and scrap reduction, lower energy use, in-mold transparency, cost control, efficient production and a digital thread for traceability on each part produced.

“The aviation industry has witnessed a paradigm shift with the introduction of sensXPERT,” Nicholas Ecke, sensXPERT application engineer contends. “The capabilities it brings to composites manufacturing will have a lasting impact on our industry, making us more competitive and sustainable.”

Read CW’s article “Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics” for an in-depth look at this Digital Mold technology.

Related Content

-

Adaptive composite elements for building facades exhibited at JEC World 2023

University of Stuttgart institutes use carbon and glass fiber composites, robotic fabrication, biomimetic design and digial twin/control to demonstrate adaptive facade elements for future buildings.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

ST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.