HAV Hydrogen obtains DNV AiP for containerized H2 system

Approval in Principle compliance shifts the standalone zero-emissions power pod for ships to first commercial deliveries and installations starting in 2024.

Six months after announcing its plans to launch a deck-based containerized hydrogen (H2) energy system for ships, HAV Hydrogen (Fosnavaag, Norway), a subsidiary of HAV Group ASA, has unveiled details of the system that has received Approval in Principle (AiP) from DNV (Høvik, Norway). The AiP is an important milestone for HAV Hydrogen in bringing the Zero Emission Pod system onto the market and engaging with customers on the first commercial installations of the system. The company told CW fiber-reinforced composite and steel tanks will be used, depending on customer preference, and is designed for operation in air temperatures between –20 to +35°C and seawater temperature from zero to +32°C.

“The AiP is based on a 20-foot container that not only contains the hydrogen fuel cells, but also the equipment required to safely run it,” Kristian Osnes, managing director of HAV Hydrogen, says. “This includes ventilation, cooling, safety systems, control system, DC/DC drives, fuel distribution system and other technical installations.”

The standalone power pod uses 200-kilowatt hydrogen fuel cells, enabling system flexibility and capable of easily providing 1,000 kilowatts within the footprint of its standard 20-foot container. By combining multiple containers, using larger modules or dedicated space below deck, multi-megawatt energy systems will also be available.

According to HAV Hydrogen, installed effect can be used for the main propulsion systems, or for additional power supply on board the vessel to comply with green operation standards. Output effect will be dimensioned to provide optimal zero emission power in desired operating situations, sailing patterns and vessel type.

Quayside, the hydrogen system ensures sufficient green power supply to the vessel, which does not need to rely on onshore charging infrastructure to achieve zero-emission status.

“The H2 system is a simple yet effective enabler of green shipping,” Osnes adds. “It can either be utilized as a retrofit option for vessels that have not already been prepared for a conventional retrofit installation below deck, or as a complete plug-in module that de-risks the yard installation for newbuilds.”

Receiving an AiP means that the H2 system has been assessed by DNV and found to comply with the current rules of the class society and applicable statutory regulations. Further, it confirms that the design is feasible and that no significant obstacles exist to prevent it from being realized.

The basis for DNV’s AiP is compliance with the safety principles of DNV rules for fuel cell installations, gas-fueled ship installations, containerized systems, the IGF Code and IMO interim guidelines for the safety of ships using fuel cell power installations.

Ultimately, HAV Hydrogen has developed the containerized, deck-based system to fast-track the commercial use of hydrogen as ship fuel. “There is significant interest from shipowners in multiple industry sectors,” Osnes explains. “We have been contacted by companies that operate within offshore wind, oil and gas, RoRo shipping, cargo, inland shipping and fishing. They acknowledge that our containerized solution can be the quick route to zero emission for their vessel types. Given that necessary infrastructure is in place, all a shipowner needs to do is to clear sufficient deck space and hook it up to the vessel’s power system.”

HAV Hydrogen currently considers short sea cargo, inland water cargo and passenger transport to be the most relevant industry segments for its containerized system, while offshore wind is expected to grow in relevance as emission regulations continue to be tightened. According to international vessel databases, including Sea-web and the European Commission’s Market Observation Inland Navigation in Europe, there are approximately 2,500 short sea cargo vessels, 7,000 inland water cargo vessels, 1,300 passenger transport vessels and 2,500 fishery vessels in Europe alone.

HAV Hydrogen will be ready to start manufacturing of the Zero Emission Pod H2 containers during the second half of 2023, aiming for the first deliveries in 2024. The company will also offer support to shipowners, ship designers and shipyards to ensure an optimal design, integration and installation process.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

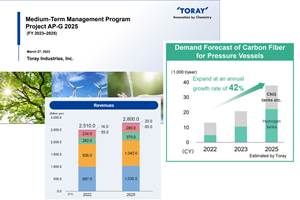

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreRead Next

Chantiers de l’Atlantique receives first initial orders for SolidSail

Chantiers de l’Atlantique equips its first sailing cargo ship and two upcoming cruise ships with its highly rigid, foldable carbon fiber SolidSail rig.

Read MoreAeler fiberglass shipping containers enhance transport insulation, payload, visibility

Unit One container is capable of transporting more cargo, reducing maritime transport emissions by 20% and incorporates embedded sensors for tracking and monitoring.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More