Hexagon Purus joins ZeroCoaster project study for hydrogen development in maritime applications

Study aims to research, evaluate and present zero-emission ship design solutions, with Hexagon Purus’ expertise in storage and distribution of compressed hydrogen gas.

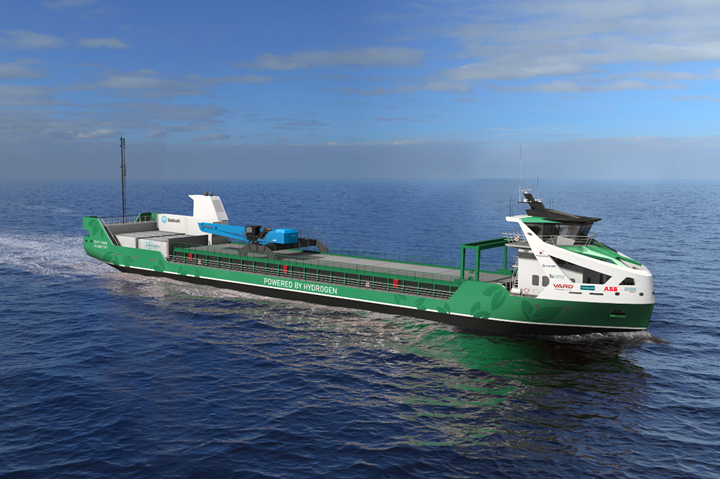

ZeroCoaster illustrated concept. Photo Credit: Hexagon Purus ASA

Hexagon Purus GmbH (Ålesund, Norway) joins the work package, Zero Emission Compressed Hydrogen (ZECH), which is part of the ZeroCoaster project study coordinated by Vard (Alesund, Norway), a global ship design and shipbuilding company. This study aims to research, evaluate and present zero-emission ship design solutions using alternative fuel systems.

The ZeroCoaster represents coastal bulk cargo operations in Norway. Systems and component solutions revealed in the project are applicable for scaling and reconfiguring for other maritime applications (see “Hydrogen is poised to fuel composites growth, Part 1”).

The project study is funded by The Research Council of Norway. One of the main objectives is to evaluate and challenge bunkering technologies and logistics operations, with a focus on safety, cost and capacity. Hexagon Purus will be contributing its knowledge and expertise in storage and distribution of compressed hydrogen gas using Type IV composite cylinder technology. Other project participants include DNV, Trosvik Maritime, SINTEF Ocean, ABB, HK Shipping, Flowchange, Statkraft.

In line with the growing national demand for zero-emission vessels along the Norwegian coast, Norway has set a target to reduce emissions by 50% by 2030. However, if Norway’s target for cutting emissions by 2030 is to be implemented, 700 low-emission and approximately 400 zero-emission ships will be required; of these 450 are bulk and cargo ships. This project aims to research and propose a cost-competitive hydrogen value chain that can support and accelerate the transition to zero-emission shipping solutions.

“We see wide benefits of working with Vard and the project partners. We have the technology needed to store and distribute compressed hydrogen in a large scale and look forward to sharing our expertise,” says Håvard Stave, technical sales manager, maritime, Hexagon Purus. “It is an opportunity for us to learn from each other, while driving the transition to zero-emission maritime applications.”

The project will be conducted using an already developed concept design platform — focused on flexibility and modularity — of the ZeroCoaster cargo ship prepared by Vard. By using simulation-driven-ship-design, the project will develop economic and technical key performance indicators (KPIs) for the use of alternative fuels on ships.

The project is scheduled for completion by end of 2021.

Related Content

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.