Ingersoll showcases 3D printed winglet layup tool at IMTS

The part was printed with large 3D printing technology developed by Ingersoll Machine Tools and Oak Ridge National Laboratory.

Ingersoll Machine Tools Inc. (Rockford, IL, US) showcased at this week’s International Manufacturing Technology Show (IMTS, Chicago, IL, US) Master Print, the company’s new large-format 3D printing technology with automatic attachment change to 5-axis CNC for aerospace-grade milling. The technology was developed in collaboration with Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US).

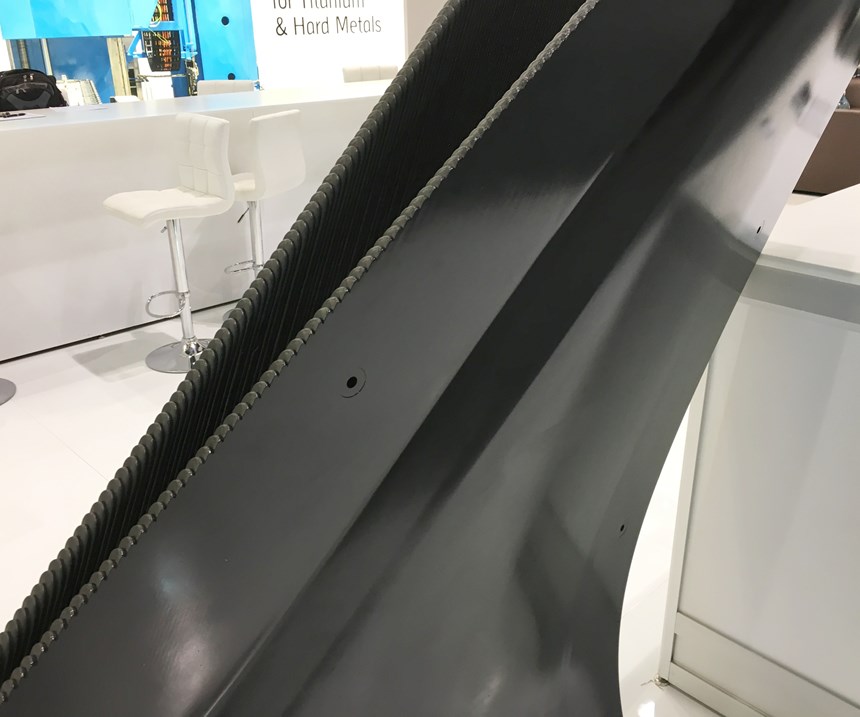

On display is the layup tool for a winglet shown in two stages. One is the just-printed tool. Second is the finished tool with sealant coating, ready to be used.

The part, says Ingersoll, weighs 430 lb/195kg and was printed in 6.5 hours. It was machined in 4.3 hours using the machine’s 5-axis technology. The material is ABS with 20% chopped carbon fiber reinforcement.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.