JEC World reveals 2022 Innovation Awards finalists

Innovation Awards celebrate successful projects and fostered cooperation between players in the composite industry, with 30 finalists in ten categories.

JEC World 2022, the world’s leading international composites trade show rescheduled for May 3-5, 2022 in Paris, France, has announced the official lineup of finalists for its Innovation Awards. The awards ceremony will be held April 26, 2022 in Paris — a week before JEC World — and will also be streamed live.

Each year, since its creation more than 20 years ago, the JEC Composites Innovation Awards celebrate successful projects and fostered cooperation between players in the composite industry. Over this period of time, the competition has shined a light on some 198 companies and 475 partners, awarding them for their excellence in composite innovations.

After pre-selection of the finalists, one winner is selected from each of 10 categories: Aerospace – Application; Aerospace – Process; Automotive & Road Transportation – Surface; Automotive & Road Transportation – Structural; Building & Civil Engineering; Design, Furniture & Home; Equipment & Machinery; Maritime Transportation & Shipbuilding; Sports, Leisure & Recreation; and Renewable Energy.

The international jury representing the entire composites value chain includes:

- Michel Cognet, chairman of the Board, JEC Group

- Christophe Binetruy, professor of mechanical engineering, EC Nantes

- Kiyoshi Uzawa, professor/director, Innovative Composite Center, Kanazawa Institute of Technology

- Jiming Sung Ha, professor, Hanyang University

- Brian Krull, global director of innovation, Magna Exteriors Inc.

- Karl-Heinz Fueller, manager future and outside materials, Mercedes-Benz AG

- Deniz Korkmaz, CTO, Kordsa Teknik Tekstil AS

- Henry Shin, head of center, K-Carbon

- Véronique Michaud, associate professor/director, EPFL – Laboratory for Processing of Advanced Composites

- Alan Banks, lightweight innovations manager, Ford Motor Co.

- Enzo Crescenti, technical authority and composite expert, Airbus

The 2022 finalists are as follows:

Category: Aerospace (Application)

Lightweight multi-material passenger aircraft seat

A lightweight aircraft seat assembly combining long-fiber prepreg sheet material and innovative multi-material topology optimization. Designed for 16G certification and mass minimization.

- Queen’s University – Structural and Multidisciplinary Systems Design Lab (Canada)

- Partner(s): Korea Carbon Industry Promotion Agency (KCARBON, South Korea)

100% thermoplastic panel for cabin interiors

Diab has developed a 100% thermoplastic and recyclable sandwich panel for aerospace cabin interiors to answer current challenges such as sustainability, REACH compliance, production rate increase, etc.

- Diab (Laholm, Sweden)

- Partner(s): Rescoll (Pessac, France), AkzoNobel (Amsterdam, Netherlands) and Roctool SA (Le Bourget du Lac, France)

HX50 Helicopter

Composite Integration developed multiple tooling and process techniques to manufacture a highly complex five-seat single-turbine helicopter fuselage as a single molding without bonded joints.

- Composite Integration Ltd (Saltash, U.K.)

- Partner(s): Hill Helicopters (Rugeley, U.K.)

Category: Aerospace (Process)

IRIS Lower Wing Cover

Fabrication process for composite aerostructures combining self-heated tooling, resin infusion and advanced automation to reduce equipment and materials cost and improve rate and design integration.

- Spirit AeroSystems (Prestwick, U.K.)

- Partner(s): Advanced Forming Research Centre (Strathclyde, U.K.) and Broetje-Automation GmbH (Rastede, Germany)

Aerospace-Grade Fiber-Steered Cylinder

iCOMAT has manufactured what is said to be the world’s first high-performance, space-grade fiber-steered cylinder, outperforming the conventional straight-fiber baseline in a structural test.

- iCOMAT Ltd. (Bristol, U.K.)

- Partner(s): Bristol University (U.K.)

Innovative Infusion Airframe Manufacturing System

Automated out-of-autoclave (OOA) portable manufacturing system for an integrated torsion box of a wing (including skin, stringers, spars and stiffeners in a one-shot part), thus avoiding assembly processes and fasteners.

- MTorres Disenos Industriales S.A.U. (Nevarra, Spain)

- Partner(s): Airbus Defense and Space (Spain)

Category: Automotive & Road Transportation (Structural)

First Competitive Structural Application — CFRTP

New design approach using endless carbon fiber for only the load paths, connecting the load paths with injection molding, no waste production in just three process steps.

- BMW-AG (Munich, Germany)

- Partner(s): BMW AG (Germany)

TUCANA is an enabler for future battery electric vehicles (BEVs) demonstrated by redesign of the whole rear body structure of a Jaguar I-Pace.

- Jaguar Land Rover (Whitley, U.K.)

- Partners(s): Broetje Automation U.K. Ltd (U.K.), CCP Gransden Ltd. (Belfast, Northern Ireland), Expert Tooling & Automation Ltd. (Coventry, U.K.), Toray International U.K. Ltd. (London), University of Warwick (U.K.) and CFMS Ltd. (Bristol, U.K.)

2021 Grand Cherokee Composite Tunnel Reinforcement

Replacement of a high-strength steel concept in a safety critical application using a pultrusion overmolded with thermoplastic to reduce weight, part count, tooling cost and meet performance.

- BASF Corp. (Florham Park, N.J., U.S.)

- Partner(s): L&L Products (Romeo, Mich., U.S.) and Stellantis (Auburn Hills, Mich., U.S.)

Category: Automotive & Road Transportation (Surfaces)

Innovation: Lightweight Multi-Material Door

Innovative new hybrid material door structure using newly developed low VOC sheet molding compound (SMC) and hybrid glass/carbon fiber SMC. The door is both paintable online and offline and meets all HMG door requirements.

- Hyundai Motor Europe Technical Center GmbH (Rüsselsheim am Main, Germany)

- Partner(s): Teijin Automotive Technologies (France)

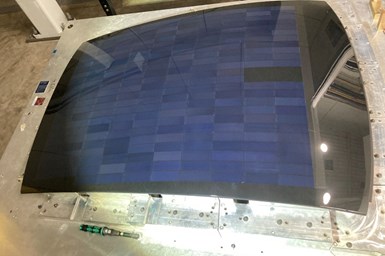

Seamless Integration of Flexible Solar Film in FRP

Seamless integration of flexible solar film in automotive fiber-reinforced plastic (FRP) components (roof top, hood, etc.) for high-volume application, using a high-pressure resin transfer molding (HP-RTM) process.

- Audi AG (Zwickau, Germany)

- Partner(s): Mubea Carbo Tech GmbH (Salzburg, Austria) and Apollo Power Ltd. (Yokneam Elit, Israel)

Light Flax Fiber-Reinforced Automotive Headliners

The objective is to develop and produce a new automotive headliner with an improved environmental assessment thanks to the use of plant fiber reinforcement instead of petro-based ones.

- Howa-Tramico (Brionne, France)

- Partner(s): Eco-Technilin (Valliquerville, France), University of South Brittany (UBS, France) and INRAe (Paris, France)

Category: Building & Civil Engineering

Structural Re-Use of Thermoset Composites

The innovative methodology of structural re-use of thermoset composites enables end-of-life (EOL) thermoset composites to be re-used in new products. It is a circular solution for these materials.

- Windesheim (Netherlands)

SOF.Radlink – Composite Radial Coupling

The SOF Radlink System enables the easy and quick connection of tunnel segments for underground infrastructure. It combines composite and thermoplastic processes for durable solutions.

- Optimas (Sarreguemines, France)

- Partner(s): Arkema (Colombes, France) and Somocap (Jaxtou, France)

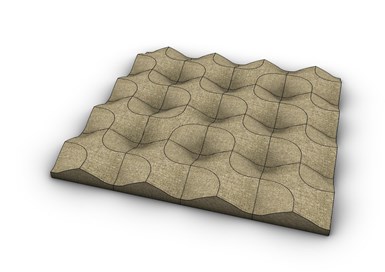

Eco Facade – Building Facade Biocomposite Panel

Sustainable, eco-friendly facade panel based on renewable materials with load-path-compatible and variable design meeting Class A fire requirements. Shading and insulation ensure energy efficiency.

- Elbe Flugzeugwerke (EFW) GmbH (Dresden, Germany)

- Partner(s) : Faserinstitut Bremen (Germany), Hightex Verstärkungsstrukturen GmbH (Klipphausen, Germany), BioMat Department – Institute of Building Structures and Structural Design (University of Stuttgart, Germany) and Fraunhofer IFAM (Bremen, Germany)

A rendition of the renewable biocomposite panels.

Category: Design, Furniture & Home

Kairlin: A New Recyclable and Compostable Material

Kairlin is a recyclable and compostable biomaterial, allowing point-of-sale and signage displays to be produced and recycled with low environmental impact, in line with the circular economy approach.

- Kairos (Paris, France)

- Partners(s): Eco-Technilin, University of South Brittany and the University of Portsmouth (U.K.)

Te Ahi Tupua – Composites & Artistic Design

The use of advanced composite materials, engineering analysis and manufacturing techniques allowed for the creation of the 12 meter x 6 meter carbon fiber sculpture, Te Ahi Tupua in Rotorua, New Zealand.

- Gurit UK Ltd. (Newport, U.K.)

- Partner(s): Kilwell Fibretube (Rotorua, New Zealand)

Gravity-Free Space Table and Floating Chair

Extremely thin and long tabletop dining table and floating chairs.

- Toray Carbon Magic Co. Ltd. (Shiga, Japan)

Category: Equipment & Machinery

Automatic Workbench For Inline Hydrostatic Testing

Automatic workbench for inline hydrostatic testing of composite pressure vessels from low- to high-service pressures. Matching line’s cadency, it adds safety and sustainability to the testing phase.

- Aumatech srl (San Salvo, Italy)

- Partners(s): ECS GmbH & Co. KG (Rimbach, Germany)

TorresPrint3D – New Large-Scale Composites Printer

TorresPrint3D is an additive manufacturing (AM) process for large components with no need for heated chamber, with variable material deposition capabilities for a more flexible, cost-efficient production.

- MTorres Disenos Industriales S.A.U.

- Partners(s): SABIC SHPP Marketing Plastics SLU (Bergen op Zoom, Netherlands)

Winding the Future - Fibraforce Technology

Fibraforce technology: Revolutionizing the high-volume production of genuine customized multi-axial thermoplastic cross-ply laminates with a continuous and ultra-fast winding process.

- Fibraworks GmbH (Roetgen, Germany)

- Partners(s): Hille Engineering GmbH & Co. KG (Roetgen, Germany), SEM GmbH (Ludwigshafen, Germany) Quality Automation GmbH (Stolberg, Germany) and Fibraforce AG (Basel, Switzerland)

Category: Maritime Transportation & Shipbuilding

InfraCore Helideck For 85-Meter Patrol Vessel

Project partners tried to design a helideck out of “classical” sandwich and did not succeed. We managed this with our patented InfraCore technology.

- InfraCore Co. (Rotterdam, Netherlands)

Marine Rotor Blades Made of Voith “Carbon4Stack”

Voith Inline Thruster CFRP rotor blades are made using Voith’s prepreg stacks (Carbon4Stack) laminate to provide ultimate vessel maneuverability to the marine industry.

- Voith Composites SE & Co. KG (Garching bei München, Germany)

- Partners(s): J.M. Voith SE & Co. KG | VTA (Heidenhaim, Germany), Gurit (U.K.) and Cotesa GmbH (Mittweida, Germany)

Composites Enable Zero-Emission, High-Speed Ferry

Wellington Electric Boat Building and its team of partners, including Gurit for lightweighting and composites, has delivered what is said to be the first fully electric, high-speed ferry in this landmark project.

- Gurit UK Ltd

- Partners(s): Wellington Electric Boat Building Co. (New Zealand)

Category: Renewable Energy

Enabling Longer Turbine Life and Operational Time

A structural adhesive designed for repair of composite wind blades in extreme conditions, able to cure at -20°C , enabling reduction of downtime for improved productivity and CO2 emissions savings.

- Huntsman Advanced Materials (Basel, Switzerland)

- Partners(s): Blade Solutions AB (Norrfjärden, Sweden)

Spabond 800 Series – Innovation In Adhesives

Gurit’s Spabond 840 is an adhesive for bonding large structures like wind turbine blades. Its innovative properties allow for shorter cycle times, ultimately reducing the cost of renewable energy.

- Gurit UK Ltd

Recyclablade windblade.

RecyclableBlade

Siemens Gamesa, in partnership with Aditya Birla Advanced Materials, has designed, manufactured and are ready to install what is said will be the first offshore wind turbine blades that can be easily dissolved and recycled.

- Siemens Gamesa Renewable Energy (SGRE, Brande, Denmark)

- Partners(s): Aditya Birla Advanced Materials (Bangkok, India)

Category: Sports, Leisure & Recreation

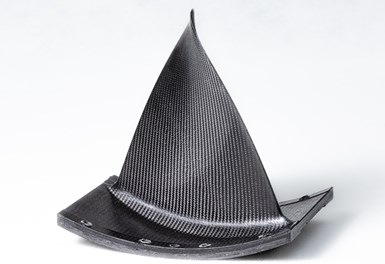

Race-Ready Bond Between Thermoset and Thermoplastic Biocomposites

Said to be the first, ready-to-market product which unites motorsport-proven natural fiber composite materials and road-focused bio-based thermoplastics with a reversible and recycling-ready connection technology.

- Bcomp Ltd. (Fribourg, Switzerland)

- Partners(s): KTM Technologies GmbH (Salzburg, Austria) Mitsubishi Chemical Advanced Materials GmbH (Sinsheim, Germany), ALBA Tooling & Engineering GmbH (Forstau, Austria) and Altendorfer Kunststofftechnik GmbH (Neureichenau, Germany)

Carbon [Fiber] Composite Flame Wheelchairs For Badminton

A composite wheelchair with novel design concepts, providing light, smooth and fast mobility due to weight reduction and high stiffness of the monocoque structure.

- Toray Carbon Magic Co., Ltd.

- Partners(s): Matsunaga Manufactory Co. Ltd. (Japan)

A Hypetex Kromaskin Field Hockey Stick For Adidas

The Hypetex Kromaskin field hockey stick for Adidas combines a unique colored carbon [fiber] spread tow outer finish with an advanced composite construction for exceptional power and consistency on the pitch.

- Hypetex (London, U.K.)

- Partners(s): Adida (Herzogenaurach, Germany), Marque Makers (Jordan, Hong Kong) and Textreme – Oxeon AB (Sweden)

Read Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More