JetZero unveils plan for BWB midmarket airliner, tanker

Blended wing body aircraft design targets need for new midmarket airplane (NMA) and defense tanker-transport program.

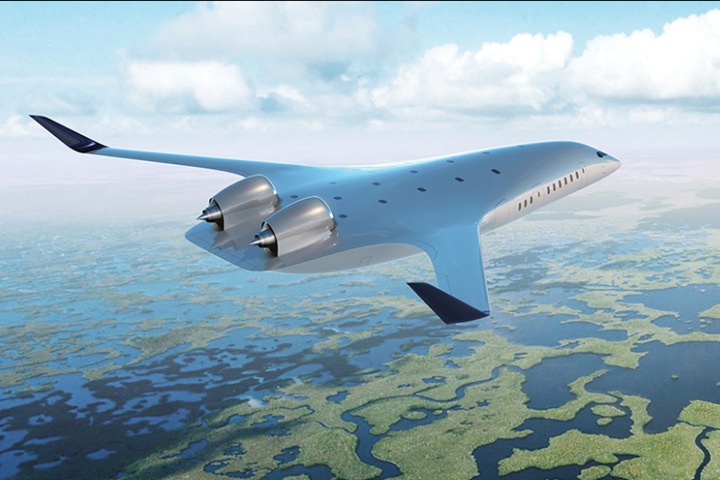

JetZero’s Z-5 all-composite BWB design features a wide single deck and high-aspect-ratio wing. Photo Credit: JetZero

California startup JetZero (Long Beach, Calif., U.S.) has unveiled an all-composite blended wing body (BWB) aircraft design targeting the commercial midsize aircraft and defense tanker-transport markets. Known as the Z-5, the aircraft is designed for a range of approximately 5,000 nautical miles and to carry up to 250 passengers.

JetZero hopes to boost the development of its commercial BWB with interest from the U.S. Department of Defense in a prototype for a large-scale advanced tanker-transport aircraft for the U.S. Air Force. According to a recent Aviation Week article, JetZero, in partnership with Northrop Grumman (Falls Church, Va., U.S.), has submitted a proposal for the Air Force program in late March, and is preparing for flight tests of a NASA-supported subscale demonstrator. The company claims that because of its fuel efficiency, the Z-5 can carry up to twice the fuel of the Boeing KC-46 tanker.

Featuring a wide single deck and high-aspect-ratio wing, the Z-5’s reduced weight and power requirements will enable the use of derivatives of existing single-aisle engines and conventional fuel tanks, while the BWB configuration affords space for liquid-hydrogen fuel tanks in the future.

The Air Force says it plans to select a winning proposal by midyear with demonstrator flights targeted for 2027. JetZero is targeting the Z-5’s entry into service in the 2030s.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.