Joint project to chemically recycle PA66 polymers using microwaves

Asahi Kasei and Microwave Chemical collaborate to commercialize a more sustainable manufacturing process to recycle PA66 using PlaWave microwave technology, and eventually also recycle polymers with fiber reinforcement.

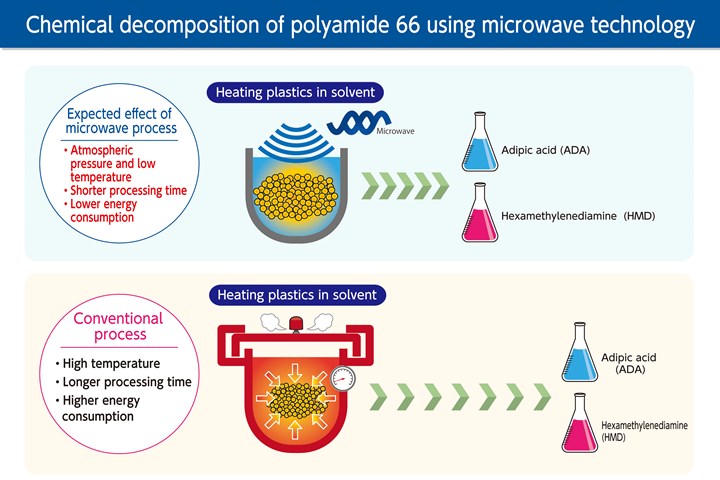

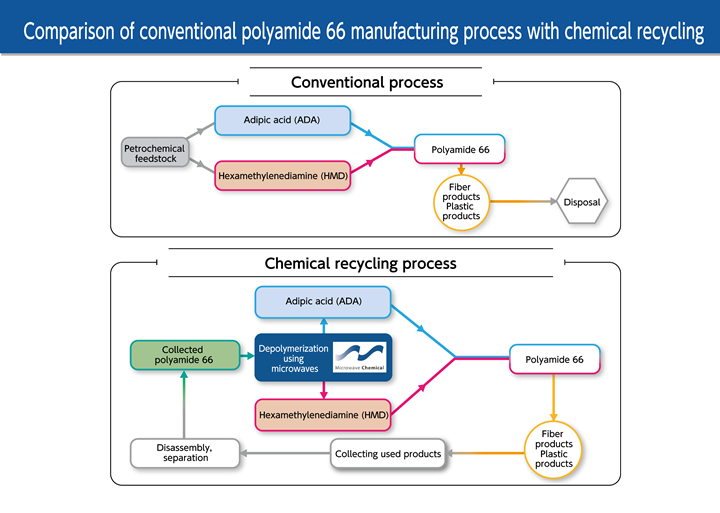

Asahi Kasei (Tokyo, Japan) and Microwave Chemical Co. (MWCC, Osaka, Japan) launched a joint demonstration project in April with the objective of commercializing a chemical recycling process for polyamide 66 (PA66) using microwave technology. The process uses microwaves to depolymerize PA66 and directly obtain the monomers hexamethylenediamine (HMD) and adipic acid (ADA), which is expected to be accomplished at high yield with low energy consumption. The monomers obtained can then be used to manufacture new PA66. In the demonstration, scraps from manufacturing and post-use waste material of PA66 for airbags and automobile parts are depolymerized. Asahi Kasei told CW that while this particular project focuses primarily on the recycling of PA66 polymers, it does aim to eventually recycle polymers with fiber reinforcement.

Asahi Kasei produces fossil fuel-derived HMD and ADA as intermediates to manufacture Leona PA66, an engineering plastic featuring high heat resistance and rigidity. However, industry attention is increasingly focused on more sustainable, carbon-neutral manufacturing methods. Microwave Chemical’s technological and business development is focused on a process development using microwaves, which can directly and selectively heat target substances with high energy efficiency which can, for example, be used to produce more sustainable carbon fiber. For chemical recycling, Microwave Chemical is advancing its proprietary PlaWave technology platform for decomposing plastic using microwaves.

Together, the two companies aim to commercialize a manufacturing process for PA66 that can reduce greenhouse gas (GHG) emissions compared to the conventional manufacturing process. Laboratory-scale studies that began in fiscal 2021 have confirmed the high-yield depolymerization of PA66 using microwaves, as well as the principle of the separation and purification process after depolymerization. Bench-scale equipment will now be assembled at Microwave Chemical’s Osaka factory by the end of fiscal 2023, and a small-scale demonstration trial using this equipment will be performed in fiscal 2024 to collect basic process data for commercialization.

Microwave Chemical’s PlaWave technology platform for decomposing plastic using microwaves can reportedly depolymerize PA66 with low energy and obtain HMD and ADA monomers in high yield. The manufacturing process for PA66 using HMD and ADA obtained by depolymerization with this technology is expected to reduce GHG emissions compared to the conventional PA66 manufacturing process, while further reduction of GHG emissions may be achieved by the use of renewable energy for the power required to generate the microwaves.

Moving forward, based on the results of the small-scale demonstration trial, a decision on the possibility of commercialization will be made by fiscal 2025 following detailed analysis. Concurrently with the small-scale demonstration trial, construction of a business model that involves the entire value chain in the chemical recycling of PA66 will be advanced, aiming to achieve a circular economy together with stakeholders in the PA66 value chain.

Asahi Kasei aims to be a global partner for its PA66 customers by providing optimal solutions for its carbon neutrality initiatives through studies of the practical application of material recycling and chemical recycling as well as trials for the commercialization of PA66 made using biomass-derived intermediates. Microwave Chemical is working to increase the scale of equipment and to make PlaWave more generally applicable in order to achieve the practical application of the chemical recycling of polymethyl methacrylate (PMMA, also called acrylic resin), automotive shredder residue (ASR), plastic containers and packaging, flexible polyurethane foam and more.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

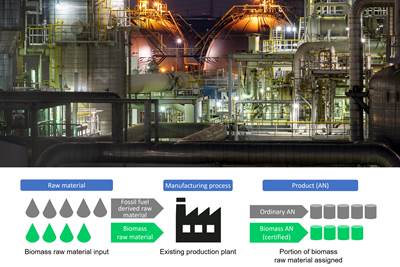

Asahi Kasei to produce acrylonitrile using biomass-derived raw material

Tongsuh Petrochemical subsidiary acquires ISCC PLUS certification and will begin production of AN using biomass propylene to make products such as ABS resin, carbon fiber and more.

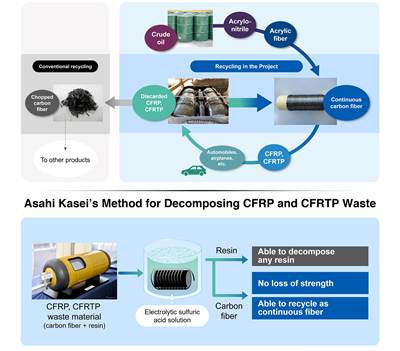

Read MoreAsahi Kasei collaborates on continuous carbon fiber reclamation development

Inexpensive, closed-loop recycling system employs electrolyzed sulfuric acid to cleanly separate the fiber from the resin.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More