Kanfit increases production throughput, improves on-time delivery with AI-based production scheduling

Plataine’s solution was implemented by Kanfit as part of its digital transformation journey to increase rate and reduce costs in the face of supply chain challenges and skilled labor shortages.

Photo credit, all images: Plataine

Kanfit (Nazareth Illit, Israel), a manufacturer of parts and assemblies for aerospace and defense markets, chose Plataine (Waltham, Mass., U.S.), a provider of Industrial IoT (IIoT) and AI-based optimization solutions, to implement its Production Scheduler to improve factory throughput, increase production rates and flexibility.

Kanfit delivers ready-to-fly assemblies and products made of composites and advanced metals and is known for its manufacturing solutions in aerospace and defense markets. Following the peak in aerospace demand, Kanfit was looking to speed up production. One of the challenges Kanfit faced was its reliance on Excel spreadsheets in its planning process. The manual method of executing the schedule hindered visibility and transparency, leading to less-than-optimal levels of control over manufacturing operations; stations, autoclaves, human resources and tools were often underutilized. Using Excel to prepare the production plan slowed down its ability to react quickly to unexpected events on the production floor.

Getting production back up to speed after COVID-19 was a priority for Kanfit. Its weekly process of production planning consumed valuable time better spent on critical tasks. Also, Kanfit’s manufacturing success was dependent on a single planner who held all the knowledge — business strategy, rules and industry insights. The company needed a solution that would not only address its immediate challenges but also lay the foundation for sustainable growth.

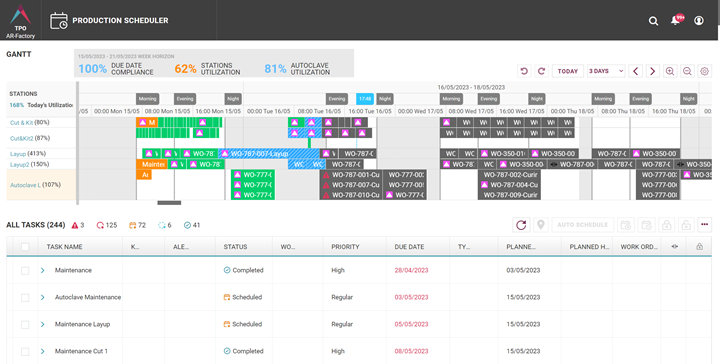

Plataine’s Production Scheduler empowers Kanfit to improve its manufacturing operations, boost efficiency and respond to market demands. The Production Scheduler is powered by Plataine’s AI Practimum-Optimum algorithm for improving production scheduling — it combines levels of key performance indicators (KPIs) with a planning application. The Production Scheduler generates a schedule with a single click to meet Kanfit’s production KPIs. In the face of unexpected events on the factory floor, the Production Scheduler reacts in real time, adjusting the schedule and promoting compliance with production objectives, and maintaining efficiency. Goals-based planning, configurable by both business leaders and the planner, provides the required flexibility.

During its initial implementation, an increase in several parameters was achieved. First time results showed 100% visibility into the production process, meaning every aspect of Kanfit’s production process synchronized with the factory floor, providing full transparency and control. The company also experienced a 15% increase in throughput in 6 months. The improvement further grew and stabilized at a 30% increase, improving the company’s throughput capabilities. Kanfit accomplished these gains without the need to invest in new machinery, hire additional employees or extend working hours, demonstrating the efficiency and impact of the Plataine solution in contrast to when it relied on Excel. Moreover, there was a 5% increase in due date compliance, further solidifying Kanfit’s commitment to delivering on time. Weekly planning time was reduced, improving operations and boosting agility.

The Production Scheduler captured Kanfit’s organizational knowledge and best practices, shifting the planner’s focus from mundane tasks to meeting growth and production goals. By maximizing production efficiency and resource use, the Production Scheduler not only addressed immediate challenges but also unlocked the door to scalability.

“Plataine’s Production Scheduler isn’t just a software solution; it’s become an integral part of our daily operations at Kanfit,” says Shachar Fine, EVP business development at Kanfit. “COVID hit us hard. Plataine’s solution has enabled us to close the gap and recover quickly. We see a significant improvement in meeting our production targets. We’ve seen an increase in our due date compliance by 5% — a considerable milestone in Kanfit’s goal to achieve operational excellence, future growth and innovation, especially during times of supply chain and workforce challenges.”

For related content, read “Kanfit increases composite material yield with Plataine AI, IIoT-based optimization solutions.”

Read Next

Plataine, NIAR ATLAS partner to promote aerospace innovation, digitalization

Researchers at NIAR ATLAS will examine how Plataine’s technology can help manufacturers and advanced composite material vendors drive further digital transformation while undertaking industry challenges.

Read MoreKanfit completes production of acceptance test part with AFP

The Ingersoll AFP machine is reported to be the first of its kind in Israel, aiding Kanfit’s R&D venture and strategy to adopt new technologies for composite production.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More