Plataine, NIAR ATLAS partner to promote aerospace innovation, digitalization

Researchers at NIAR ATLAS will examine how Plataine’s technology can help manufacturers and advanced composite material vendors drive further digital transformation while undertaking industry challenges.

Plataine (Waltham, Mass., U.S.), provider of AI and industrial IIoT-based manufacturing optimization solutions, announces a partnership with the Advanced Technologies Lab for Aerospace Systems (ATLAS), part of the National Institute for Aviation Research (NIAR) at Wichita State University (WSU, Kan., U.S.), to explore opportunities for further digital transformation of advanced manufacturing processes through data analytics.

Carbon fiber materials will be tracked using Plataine’s time-sensitive material management technology for advanced manufacturing and aerospace composites. Plataine says this will demonstrate effective digitization of the composite process and time-sensitive material management best practices to the next generation of advanced material leaders.

Researchers at NIAR ATLAS will examine how Plataine’s technology can help manufacturers and advanced material vendors drive innovation while undertaking industry challenges such as labor shortages, supply chain disruption, sustainability and delays caused by use of expired materials.

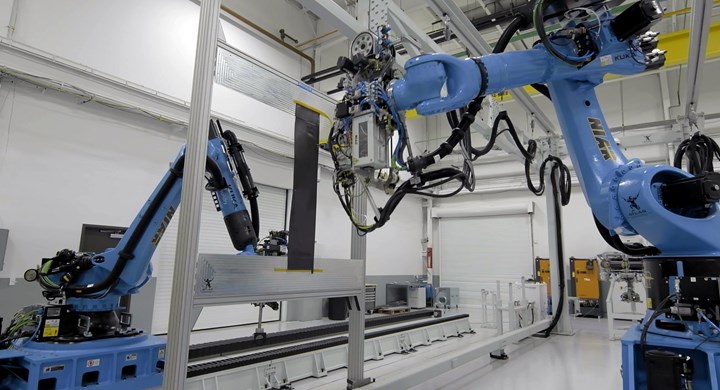

NIAR has a strong history in aviation industry research, and the partnership with Plataine will build on its advanced manufacturing research and development to fuel further innovation. ATLAS provides a multidisciplinary manufacturing and applied learning environment, and Plataine will make full use of the facility’s state-of-the-art machines, software and processing technologies.

“We are proud to partner with NIAR of Wichita and are looking forward to finding new ways to tackle the challenges of our industry through digitization and automation of factories,” Avner Ben-Bassat, CEO and president at Plataine, says. “Working alongside individuals who share our commitment and vision of delivering groundbreaking innovative technology to the aviation industry is a privilege.” Ben-Bassat adds that his partnership will prepare engineers and educators for the Factory of the Future, demonstrate new ways for manufacturers to meet increased production demand and help current workforces make the seamless transition to advancements in the workplace.

NIAR has built a strong relationship with various divisions of the U.S. Department of Defense (DOD), leading in a fifth place ranking among U.S. universities in a list of federally funded aerospace R&D expenditures, with $63 million in funding.

According to Dr. Waruna Seneviratne, director of NIAR ATLAS, “Being a part of the applied learning ecosystem at Wichita State and working with our industry partners, NIAR researchers are dedicated to driving innovation, advancing knowledge and defining best practices in the field of aviation and composites. Working with Plataine dovetails with our vision, enabling us to continue looking toward the future of advanced manufacturing and inspiring the leaders of tomorrow.”

Related Content

-

DLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

Com&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.