Lanxess certifies carbon footprint of base resins, fiber reinforcement

Industry comparison confirms significantly lower CO2 emissions during PA6, PBT and glass fiber production. Carbon footprints of compounds to be available soon.

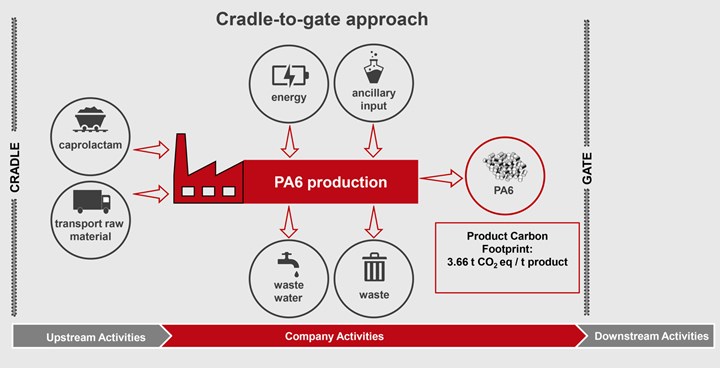

The carbon footprint of various products such as the PA6 base resin were calculated in accordance with the standard ISO 14067:2018. The analysis factored in all the major emissions that occur up to the point at which the product leaves Lanxess (cradle-to-gate). Photo Credit: Lanxess

Lanxess (Cologne, Germany) is now offering customers — specifically those processing Durethan polyamides and Pocan polyesters (PBT) — certified values for the carbon footprint of the base resins. Certification was done by an accredited verification body and includes not only the polyamide 6 (PA6) precursor caprolactam but also the glass fibers manufactured by Lanxess in Antwerp, Belgium.

“These certified values enable our customers to more accurately estimate the climate friendliness of their products and identify ways of further reducing their CO2 emissions,” Guenter Margraf, head of sustainability and product management in the High Performance Materials (HPM) business unit, says. “The values are also an important part of life cycle analyses, which are increasingly being used in the automotive and electrical and electronics industry to systematically analyze how products impact the environment from manufacturing through to disposal.”

The values were calculated according to the standard ISO 14067:2018 for the carbon footprint of products. The analysis factored in all the major emissions that occur up to the point at which the product leaves the Lanxess factory gate (cradle-to-gate). These include not only direct emissions (scope 1) but also indirect emissions from the purchase of energy (scope 2) as well as the emissions that occur in the upstream supply chain, for example those associated with the raw materials used and transportation processes (scope 3).

Lanxess is looking to use the certified carbon footprints for identifying ways to reduce the level of greenhouse gases (GHGs) emitted during plastic production.

“We were especially pleased to learn that, with 3.66 metric tons of CO2 equivalents emitted per metric ton of PA6 produced, the carbon footprint of our PA6 base resin is much smaller than the current published European industry average,” Margraf adds. One reason for this is that Lanxess synthesizes the plastic in a highly integrated plant network in Antwerp. From 2024 onward, the carbon footprint of PA6 production is set to improve significantly yet again when, in 2023, if all goes to schedule, the company will be opening a second nitrous oxide reduction facility. “Reducing nitrous oxide cuts the direct emissions associated with PA6 production by almost 90%,” Margraf says. Lanxess is also looking to use sustainable raw material sources for caprolactam with a goal to reduce the carbon footprint of its PA6 to less than three metric tons of CO2 equivalents. The certification also revealed that the carbon footprint of its PBT base resin was less than that of many other manufacturers.

In glass fiber production, Lanxess also cites a significantly smaller carbon footprint compared with most of its competitors. “This applies in particular to our resource-efficient Eco glass fibers, which, with a carbon footprint of 0.4 metric tons of CO2 equivalents per metric ton of glass fiber, save more than 70% of emissions compared with the published industry average. We use industrial glass waste in our production, which reduces the consumption of raw materials and energy and avoids waste,” Margraf notes.

Lanxess is looking to use the certified carbon footprints for identifying ways to reduce the level of greenhouse gases (GHGs) emitted during plastic production. One focus is on the use of sustainable raw materials. New product ranges such as Durethan Blue, Durethan Eco or Pocan Eco are currently being extended that contain a significant proportion of circular (recycled or bio-based) raw materials or have a carbon footprint that is considerably smaller than conventional products. The sustainable origin of those raw materials is certified according to the International Sustainability and Carbon Certification (ISCC) Plus standard. The certification is coupled with mass balancing, which enables the share of sustainable material in the end product to be determined and subsequently indicated in a transparent manner for processors. One product example is the 60% glass fiber-reinforced Durethan BLUEBKV60H2.0EF. In this PA6 compound, 92% of the raw materials have been replaced by sustainable alternatives, according to the company.

In August 2022, the specialty chemicals company announced its mission to make its upstream and downstream supply chains climate-neutral by 2050. This encompasses indirect emissions associated with purchased raw materials in particular, but also emissions associated with its logistics processes and end products. By 2030, the aim is to cut scope 3 emissions by 40% compared with the reference year 2015. For direct emissions in production (scope 1) and energy sources (scope 2), Lanxess announced three years ago its intention to achieve climate neutrality by 2040.

Related Content

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

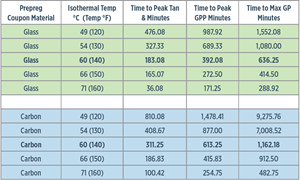

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreRobotized system makes overmolding mobile, flexible

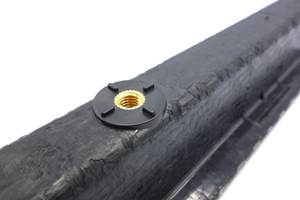

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

Read MoreRead Next

Teijin introduces LCA for carbon fiber intermediate materials

Life cycle assessment (LCA) studies calculate the environmental impact of Teijin composites for future emission reduction activities.

Read MoreCarbon fiber enables new, low-CO2 Skyrora orbital launch vehicle

U.K. private space company is developing and testing orbital launch vehicle Skyrora XL to carry small satellites in Earth’s orbit using eco-friendly fuel, a unified systems design and composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More