LATTE project optimizes aerodynamic flow of RACER rotor head

Composites and streamlined rotor head design to enable up to 5% reduction in drag and as much as 20% lifting force improvement for Clean Aviation helicopter, set for flight tests in 2024.

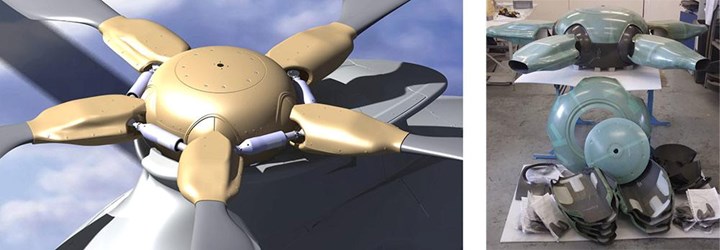

RACER helicopter rotor head bringing optimized aerodynamic flow. Photo Credit, all images: LATTE consortium

Clean Sky 2’s (now known as Clean Aviation) Rapid and Cost-Effective Rotorcraft (RACER) demonstrator, which aims to demonstrate faster, lighter and more ecologically sustainable compound rotorcraft architecture is on the verge of taking to the skies in 2024. A multitude of projects have contributed to the RACER’s composites-intensive design and engineering (read CW’s “Optimizing AFP for complex-cored CFRP fuselage” for more information). One of these, the recently completed LATTE (Full Fairing for Main Rotor Head of the LifeRCraft) project, which spanned September 2017 to June 2023, focused on the design and production of a distinctive rotor head assembly/fairing for the RACER.

The rotor head is a critically important component of the helicopter and is located at the intersection between the rotor blades and the mechanical assembly above the pilot/passenger cabin canopy. It transmits rotational power from the engine via the shaft to the rotor blades, and also controls the pitch of the blades — which determines the attitude of the helicopter. In a nutshell, the rotor head is key to the lift and forward (or lateral) propulsion characteristics and performance of the RACER.

Typically, a rotor head has exposed structures which generate drag during flight and therefore slow down the helicopter. LATTE sought to solve this by encapsulating the rotor head within an aerodynamic fairing — a feat which required overcoming significant mechanical complexities. The project encompassed the design, development and manufacture of a set of composite parts in conformity with airworthiness standards. The consortium, coordinated by the Lukasiewicz Institute of Aviation (ILOT, Poland), comprised of three partners, including Czech National Center for Research, Development and Testing in Aerospace VZLU and Czech composite parts manufacturer LA Composite (Prague). Airbus (Toulouse, France) was the topic manager.

“This innovative rotor head includes a partial air sealing function, which makes it possible to drastically reduce the drag of the helicopter at the high cruise speeds the RACER will achieve,” Clean Aviation project officer Vincent Foucart says. “The LATTE design directly contributes to the RACER concept’s efficiency while also reducing emissions.” The hardware delivered by the LATTE project will be installed on the RACER demonstrator in 2024, soon after the initial flight test campaign has opened the flight envelope at lower speeds.

To ensure effective performance of the hardware to assure these higher speeds, test campaigns and extensive component quality checks and approvals were undertaken prior to delivery of the parts to Airbus. These activities culminated in a first article inspection and associated documentation which was supplied alongside the parts. Further verification of the entire assembly was performed using a special test jig to ensure dimensional fidelity which will facilitate its ongoing installation onto the RACER demonstrator.

Equipped with the LATTE fairings, the consortium says that drag will be reduced by 5% and lifting force can be increased by 20%. This will enable the RACER to operate at higher cruise speeds while lowering fuel consumption (which means less emissions). Additional benefits of the rotor hub fairing are reduced noise and mechanical stress on the tail of the helicopter, due to the reduction of vibrations that would otherwise occur as a result of turbulent airflow generated by having an exposed rotor hub.

“Designing such a complex assembly, primarily made of lightweight composite materials and operating with the loads and within the severe vibration environment of a helicopter rotor, was a tough engineering challenge,” Foucart notes. “The LATTE project team has shown that it was up to this task, with the successful delivery of the parts to Airbus Helicopters, with all associated data to support the permit to fly.”

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreRead Next

New Clean Aviation projects to facilitate highly efficient aircraft by 2035

Clean Aviation, approved for €380 million to advance eight topics revolving around new aircraft concepts and propulsion architectures, reveals project focuses and partners.

Read MoreRACER achieves “power on” test, prepares for 2023 maiden flights

Initial function checks were conducted at the Airbus Helicopter facility in Marignane, France, signaling the next step for the composite rotorcraft demonstrator and its highly collaborative teams.

Read MoreGKN Aerospace, Airbus Helicopters progress industrial partnership

A signed MOU covers multiple projects and work packages related to the H225M helicopter’s engineering, EWIS design and manufacturing, MRO, composites design and more.

Read More