Magnetic nanoparticles show promise for thermosets recycling

Aitiip and the University of Slovenia have collaborated to develop, test and prove how smart magnetic nanoparticles can produce a controlled decomposition of the resin for recycling.

Source | Aitiip Technology Center

Aitiip Technology Center (Zaragoza, Spain) is researching the synthesis of chemical additives that respond to thermal stimuli to facilitate the decomposition of thermoset resin in controlled chemical reactors. This process seeks to enable separation of the fibers — usually glass or carbon fiber — from the rest of the resin and the reuse of both components, as demonstrated in the VIBES research project.

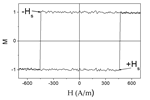

Thermoset resins, true to their name, are difficult to recycle due to their irreversible nature and resistance to thermal degradation. To target these challenges, Aitiip, participating in the IPPT_TWINN project led by the University of Slovenia’s (Ljubljana) Polymer Technology faculty, is helping to develop smart magnetic nanoparticles, which have been subjected to a magnetic field. These particles are integrated into a thermoset resin before curing. When it is time to recycle the material, a magnetic field can be applied; this induces a controlled breakdown of the polymeric network, facilitating the separation of the fibers from the rest of the material.

This breakdown of the material’s chemical structure then serves as a pre-treatment to facilitate chemical solvolysis, enabling more rapid decomposition of the resin, thus also speeding up the recycling process and reducing waste.

Characterization tests are currently underway to assess the impact on the resin system’s properties. Next steps also include determining whether these particles can further improve the efficiency of the chemical solvolysis process.

Related Content

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.