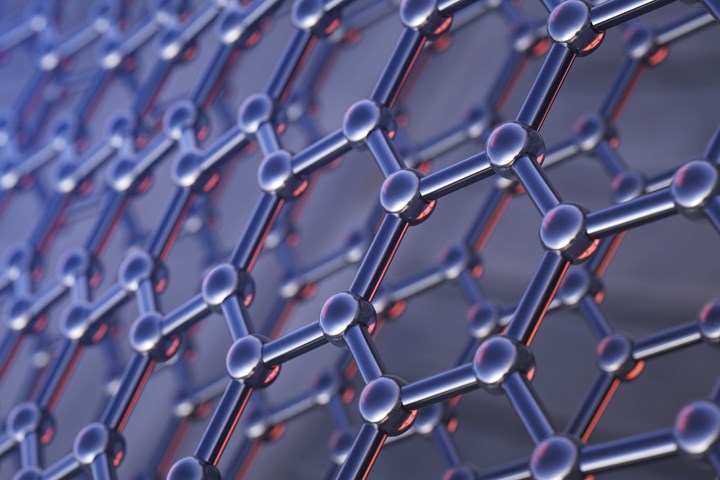

MITO spearheads graphene classification initiative that can aid in composites industry adoption

MITO vice president, Caio Lo Sardo, takes leading role in graphene framework intended to provide standardized referencing protocol, preferred test methods and their range of values, and important data to lower barriers to commercial adoption.

MITO Material Solutions (Indianapolis, Ind., U.S.), a developer of additives that enable polymer manufacturers to enhance product performance, announces that its vice president, Caio Lo Sardo, has taken a leading role in what is said to be the first graphene document in development led by the U.S. committee within the International Organization for Standardization (ISO) Technical Committee (TC) 229, Nanotechnologies.

Lo Sardo was recently nominated to serve as project leader on the “Classification Framework for Commercial Graphene-Related 2D Materials” as part of a global graphene classification process submitted by American National Standards Institute (ANSI)-Accredited U.S, Technical Advisory Group (TAG) to ISO/TC 229. Products originating as graphite are said to be complex with numerous variations which impact their viability. Right now, when buying graphene-based products, no standard exists to ensure the product purchased will have the required qualities for application needs.

According to Lo Sardo, multiple companies have struggled to have materials approved for EPA/TSCA registration, despite following proper processes and using expert guidance. The lack of a clear, consistent framework for the classification of the many different forms, or “grades” of graphene-related materials causes confusion and is an obstacle to commercial adoption. This confusion extends to the regulatory community (EPA, FDA, REACH) and the challenge of being able to consistently, efficiently and reliably regulate graphene materials.

When asked by CW how this standardization impacts the use of graphene in composites, Lo Sardo noted, “In order for this industry to reach its fullest potential, we need to agree on what metrics we’re looking at to quantify and qualify. Near term, that means it is important for us to understand the material’s characteristics, which requires everyone to use the same nomenclature and metrics for their graphene materials.”

The new standard intends to classify all types of graphene-related 2D materials (GR2M) including: monolayer/single-layer graphene, bilayer graphene, trilayer graphene, few-layer graphene, graphene nanoplatelets, graphene oxide and reduced graphene oxide. This project will establish consensus-based parameters for commercial graphene purchases to confirm the material meets the expected standards.

“Critical and emerging technologies, such as those enabled by graphene are revolutionizing the composite manufacturing industry.”

“It was a natural fit for MITO Materials to support this project. Our flagship product, E-GO, is a graphene-based additive that contains functionalized graphene oxide. We know from our work with manufacturers that the quality and characteristics of the graphene is critical to the success of the final process,” Lo Sardo comments. “When Dr. Hight Walker nominated our CEO, Haley Marie Keith, and me to participate in the project we were immediately on board. I’m honored to serve as project lead on the Graphene Framework within Working Group 4, Material Specification.”

The proposed graphene standard is based on a framework outlined by The Graphene Council (New Bern, N.C., U.S.), which was developed in an industry peer-reviewed process. The Graphene Council is reportedly the largest community in the world for graphene researchers, producers and users, connecting more than 30,000 materials professionals. Lo Sardo took the initiative to make the framework official by developing it as the globally recognized ISO standard. He pitched the proposed classification process to ISO TC 229 Working Group 4, with a proposal where the document released by the council would be the starting point for development under ISO.

MITO ice president, Caio Lo Sardo, leads the graphene initiative. Photo Credit: MITO Material Solutions

Every aspect of the material is considered during the standards’ creation process including the most adequate testing method and the ranges of values each characteristic should be within. This global project will establish base parameters for 19 characteristics of the material: raw material, material form, sp2 bonded carbon, structural defects, Z-axis dimension, layers of carbon atoms, particle shape, lateral particle dimensions, particle aspect ratio, bulk density, elemental composition, oxygen content, impurities, functionalization, surface particle charge, orientation, specific surface area and crystallinity.

ISO/TC229 consists of five international Working Groups developing standards in the following areas:

- WG 1 focuses on terminology and nomenclature with leadership assigned to Canada (SCC).

- WG 2 focuses on measurement and characterization with leadership assigned to Japan (AIST).

- WG 3 focuses on health, safety and the environment with leadership assigned to the United States (ANSI).

- WG 4 focuses on materials specifications with the leadership assigned to China (SAC).

- WG 5, the newest WG, focuses on performance-based standards for nano-enabled or nano-enhanced products and applications.

Due to the critical nature of graphene to the manufacturing industry, the classification project is on an accelerated timeline. By the end of summer 2022, it is set for revision of comments and inputs for editing. Future presentation is to be held at the general November meeting of ISO TC 229 Committee with expected outcome of a voting ballot followed by official publication, when approved.

“We are thrilled that MITO Materials is leading the development of the classification framework for commercial, graphene-related 2D materials within ISO/TC 229. [ISO/PWI 9651]. U.S. industry leadership in documentary standards is key to our nation's success and facilitates international trade,” Dr. Angela Hight Walker, standards expert and senior scientist at NIST, adds. “Critical and emerging technologies, such as those enabled by graphene are revolutionizing the composite manufacturing industry. Companies like MITO Materials will eventually have consensus-developed metrics to validate advanced materials used in their processes.”

Read Next

3D-printed, self-assembled graphene demonstrates potential for hierarchical composites

A 3D-printed template-directed assembly method assembles graphene into a multi-scale programmed structure with tunable mechanical properties, low density and high Young’s modulus.

Read MoreOCSiAl expands graphene nanotube production capacities to Europe

The new synthesis facility near Belgrade, Serbia, will be launched in the first half of 2023, with a planned capacity of 40 metric tonnes/year. Production will be leveraged for various polymers and nanotube dispersions to boost EV battery density.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More