MVP facility expansion strengthens Tennessee manufacturing operations

Relocation of its manufacturing center to the East Tennessee facility boosts capacity by 25%, facilitates more process, decision-making and collaborative flow.

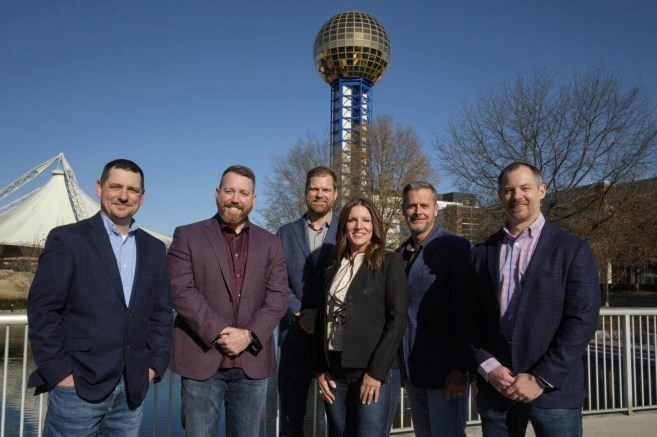

MVP’s executive leadership team (from left to right) : Travis Silcox, Andrew Hedger, Scott Andrews, Amber Holt, Tobi Ferguson and Brady House. Source | Magnum Venus Products (MVP)

Magnum Venus Products (MVP, Knoxville, Tenn., U.S.), a global manufacturer of fluid movement and production solutions for industrial applications, continues to increase production capacity in Tennessee to better serve its customers globally. After purchasing 17 acres of land and a 125,000-square foot facility in East Tennessee last year, MVP has relocated its manufacturing center to the East Tennessee facility this April, boosting production capacity by 25% and enabling greater scalability for the future.

The decision to strengthen manufacturing operations in Tennessee stems from the strategic alignment of machining and fabrication capabilities with existing assembly facilities at MVP’s Knoxville location. By consolidating these operations from Kent, Washington, to Knoxville, MVP is not only optimizing logistical processes but also paving the way for future growth opportunities. The corporate office is also situated in Knoxville, facilitating cross-functional collaboration and accelerating decision-making processes. MVP also notes that its production increase will bring job opportunities for Tennessee residents.

“With the rapid surge in demand triggered by the challenges of the pandemic and the subsequent years, it became evident that we needed to streamline our operations, bolster resources and strengthen our core capabilities to adequately address the escalating demand,” notes Travis Silcox, vice president of operations at MVP. “Through the establishment of more dependable supply chain networks and enhancements in process flow, we have transformed our operations. Now, equipped with our upgraded facility, we are well-prepared to efficiently handle the increased order volume.”

Designed to foster innovation and collaboration, MVP’s new facility encompasses dedicated spaces for R&D, accelerating the exploration of new technologies and solutions to meet evolving market demands. The facility also includes ample room for hosting customer events and training, providing a platform for engaging with partners, sharing insights and showcasing latest advancements. Additionally, the new location features an expanded technical service center, and a new production layout and inventory management systems to enhance process and workflow efficiencies.