Century Tool investment boosts efficiency, capability in tooling for composites

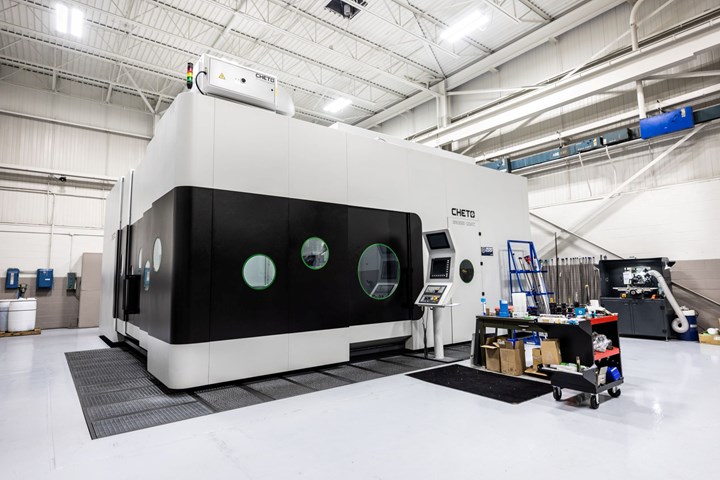

Designer and builder of compression molds for composite structures installs seven-axis CNC deep-hole drilling and milling machine to improve productivity.

Century Tool (Fenton, Mich., U.S.), a Tooling Tech Group company and a composites tooling specialist, has announced it has invested in a Cheto (Lote, Portugal) IXN 3000 — a seven-axis CNC deep-hole drilling and milling machine tool and one of only five in the U.S. Designed to enhance the moldmaking process, the Cheto IXN 3000 offers deep-hole gundrilling on one side with the capability of changing out the gundrill bit from a five-gun locker. On the milling side, the machine features a 50-gun locker for changing out cutting tools.

Century builds high-quality compression molds for composite components used in a variety of industries. Its capabilities extend to SMC, BMC, GMT, DLFT, RIM, RTM and DCPD molds, addressing aerospace, automotive, bath and spa, energy, heavy truck and powersports markets.

“We are excited to add this new capability to Century Tool,” says Lee Childers, Tooling Tech Group CEO. “The Cheto machine allows us to improve productivity by stringing together gundrill and milling programs, unattended, for up to 48 hours. And these machines are recognized for the steadiness and balance of their drills, all helping us better serve our customers.”

The Cheto IXN 3000 provides a spindle speed of 6,000 rpm and a 60,000-pound capacity. It enables Century Tool to drill as deep as 98 inches, as well as drilling more than three times faster than previous machines. Additionally, the system has the ability to monitor tool wear, helping to reduce tool breakage and increase uptime without operator intervention.

In addition to the Cheto IXN 3000, Century Tool has also invested in the company and the market with the recent purchase of Fidia five-axis and Toshiba three-axis machine tools.

Related Content

-

Jamco America partners with Airtech for 3DP tool recycling

Aerospace manufacturer joins forces with composite materials company to achieve sustainable manufacturing practices that overcome traditional composite layup tooling.

-

Metal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

-

Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.