Magnum Venus Products

Knoxville

2030 Falling Waters Rd.

Suite 350

Knoxville, TN 37932 US

800-448-6035 | 800-448-6035

info@mvpind.com

mvpind.com

About Magnum Venus Products

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Magnum Venus Products Supplies the Following Products

- Adhesive applicators

- Adhesive bonding

- Bladder molding equipment (formerly pressure bag)

- Bonding equipment

- Carbon fiber composite

- Ceramic matrix composite casting

- Choppers

- Coaters

- Coating and painting

- Composite, other

- Consulting, environmental

- Consulting, materials

- Consulting, process development

- Continuous laminating

- Continuous laminating machines

- Education/Training

- Emission control devices

- Environmental testing equipment

- Fiberglass composite

- Filament winding

- Filament winding machines and controls

- Flow meters

- Flow-coating equipment

- Gel timers

- Hand layup

- Hand layup tools (cutters, rollers, scissors, etc.)

- Heaters

- Hoses, pressure

- Hoses, vacuum

- Impregnation lines

- Impregnation lines, film-based

- Inserts

- Machine calibration services

- Mandrels, other

- Material handling equipment

- Metering/dispensing equipment

- Mixers

- Moldmaking and patternmaking

- Ovens

- Preform manufacturing equipment

- Prepreg

- Pultrusion equipment, thermoplastics

- Pultrusion equipment, thermosets

- Quick disconnects for vacuum hoses

- Repair kits and equipment

- Repair services, equipment and machines

- Resin injection

- Resin injection equipment, pultrusion

- Resin transfer molding (RTM)

- Resin transfer molding equipment (RTM)

- Resin wetout equipment, pultrusion and filament winding

- RTM/resin infusion

- Spray booths

- Spray guns

- Sprayup

- Tape laying

- Used primary equipment

- Vacuum valves and pumps

- Vacuum-assisted resin transfer molding (VARTM)

- Vacuum-assisted resin transfer molding equipment (VARTM

- Winders/rewinders

Editorial, News, and Products

-

VIDEO: Painting parts with self-learning robots

LestaUSA’s self-learning robots on display at CAMX 2024 enhance composites manufacturing workflow and workforce needs.

-

MVP partners with LestaUSA to bring robotics to composites

Self-learning robotic solutions are designed to simplify the automation process for composites manufacturers of all sizes wanting to incorporate automated spray applications.

-

IPD system, robotic spray demonstration enhances composites productivity

CAMX 2024: Magnum Venus Products (MVP) presents several automation solutions, including a self-learning robot, an IPD system and several live demonstrations of its products.

-

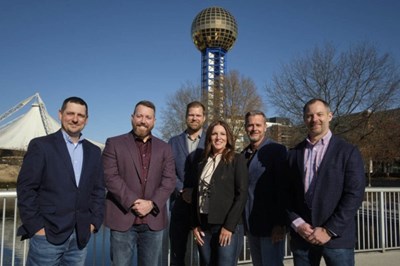

MVP facility expansion strengthens Tennessee manufacturing operations

Relocation of its manufacturing center to the East Tennessee facility boosts capacity by 25%, facilitates more process, decision-making and collaborative flow.

-

Live demonstrations present closed molding advancements

CAMX 2023: The Composites One and Closed Mold Alliance demo zone returns with short but engaging exhibitions featuring vacuum infusion, reusable bag molding, light RTM and other technologies through the show.

-

Magnum Venus Products to expand capacity in Tennessee

MVP will spend $20 million over five years to build a new 125,000-square-foot manufacturing facility in East Tennessee.

-

Digital Demo: Secure Vacuum Bag Seal Eliminates Single-Use Sealant Tapes in Closed Mold Process

Magnum Venus Products (MVP) has developed a reusable two-part seal for the vacuum infusion closed mold process, replacing single-use sealant tapes. (Sponsored)

-

Dow Chemical, MVP introduce polyurethane-enabled LRTM process

Transportation industry solution decreases LRTM injection times using specialized three-component material chemistry and fully automated injection unit with Fast Flow LRTM process.

-

MVP introduces CARE, a new technical service solution

CARE program supports a wide variety of technical services to eliminate manufacturing downtime, parts availability, labor shortage and improper equipment maintenance roadblocks.

-

CAMX 2022 exhibit preview: Magnum Venus Products

Rather than sealant tapes for infusion processes, Magnum Venus Products suggests the use of its Secure Vacuum Bag Seal, an inflatable seal designed to fit into a groove built into the perimeter of the mold.

-

Low-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

-

Composite rotary milking platform evolves via process innovations

Infusion and LRTM-based processes and design enabled Waikato Milking Systems to bring a lighter, less labor-intensive platform to the global dairy market.

-

Magnum Venus Products expands international distribution network

Addition of Norwegian distributor, Hans Claussen AS will provide industrial equipment for open, closed molding processes, adhesive applications and automation solutions.

-

Composites One finalizes agenda for “From Space to Sea” composites workshop

The free, two-day event occurring mid-April will host live demonstrations and presentations geared toward a wide range of experience levels, from professionals to students.

-

Composites One opens registration for advanced materials workshop in April 2022

“Space to Sea: Composites Are Changing the Way We Make Parts” is a free, two-day session to be led by Composites One, the Closed Mold Alliance and IACMI.

-

MVP releases new model of RAM system for thermoset materials

New large-format AM machine model, RAM 48, maximizes production efficiency and enables custom build dimensions when fabricating thermoset materials.

-

MVP large-format system prints thermoset resins

Magnum Venus Products’ Reactive Additive Manufacturing (RAM) system is a large-format AM machine that prints with fiber-reinforced thermoset resins.

-

MVP welcomes Tobi Ferguson as president and CEO

Ferguson brings his history of innovation, collaboration and customer experience to maximize MVP’s business growth potential.

-

Large composite covers protect a lot of water

A massive concrete water storage facility in Bogotá, Colombia, gets a much-needed makeover with the resin transfer molding of 840 large composite domes that keep the water potable.

-

MVP launches Fast Flow LRTM process to speed closed mold part production

Increasing part production by decreasing injection times, Fast Flow LRTM is said to be capable of injecting a 50 square foot part in under four minutes using only one injection port.

-

Revisiting the Fundamentals of Light Resin Transfer Molding (LRTM)

Like other closed molding composites processes, Light Resin Transfer Molding (LRTM) offers reduced waste and emissions, efficient materials use and a consistent and repeatable process. But LRTM requires less costly tooling and can still provide excellent cosmetics on both sides of a part in an efficient manufacturing process.

-

Soling, Magnum Venus Products partnership produces LRTM composite domes

Incorporating the LRTM process enabled Soling to produce the largest LRTM part by volume manufactured in Colombia.

-

Magnum Venus Products partners with Australian distributor

The new distributor, MVP Australia, will support MVP’s composite equipment and streamline MVP’s customers’ manufacturing processes.

-

Magnum Venus products launches fusion filament winder

Ideal for winding pressure vessels, the Fusion filament winder is a compact, adaptable design.

-

Composites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

-

Additive manufacturing reimagined: large-scale, fiber-reinforced thermoset printing

ORNL, MVP and Polynt-Reichhold launch world’s first commercially available, large-scale thermoset composite additive manufacturing machine and reactive print material.

-

Composite catamaran hits high watermarks

Inspired by design elements found in racing catamarans and employing composite structures in innovative ways, Compmillennia has rolled out a fishing/excursion cat that uniquely combines high speed, great fuel economy and a smooth ride.

-

IACMI to host training workshop with Composites One, Closed Mold Alliance

The workshop will be held at the Composite Prototyping Center on June 11-12, 2019.

-

People on the Move: May 2018

CW’s monthly roundup of people on the move in the composites industry.

-

MVP and ORNL install first commercially available medium/large-scale thermoset 3D printer

MVP engaged with ORNL to create a 3D printer capable of printing large-scale thermosets, chemistries that are irreversibly cured from a prepolymer or resin.

-

Composites One and IACMI partner for Road2Composites workshop

The Road2Composites Workshop will take place in Detroit, April 17-18.

-

IBEX 2016: New access to composites

Composites Pavilion hosted Composite Tech Talks and the interactive Future Materials exhibit.

-

JEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.

-

CAMX 2015: More green, more customization, more growth

CAMX, the second year, was in interesting event, marked by a lot of enthusiasm, a lot of innovation and many new products.

-

FRP challenges conventional frame-and-drywall construction

A multinational builder and a machinery manufacturer join forces to bring an automated composite panel molding system to the residential construction market.

-

Modular composite tank kits

This fluid-storage tank component supplier employs Europe’s largest reusable vacuum bag

-

Exelis Aerostructures: Salt Lake City

Braided composite shafts and struts for aircraft are its specialty, but there’s much more to this Utah, US-based rising star.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Meter/mix/dispense machines: The suppliers and systems

HPC’s meter/mix/dispense (MMD) roundup includes this collection of the principle suppliers of MMD equipment and equipment characterizations.

-

Meter/mix/dispense machines: Doubling down on control

The latest equipment solutions deliver lower costs, faster cycle times and better part properties.

-

Reusable vacuum membranes: Coming of age?

Durable custom elastomeric bags cut consumables cost and boost rate production.

-

JEC Europe 2013 new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display.

-

IBEX 2011 Review

As the International BoatBuilders’ Exhibition & Conference again docks in Louisville, the industry continues a slow and tentative rebound.

-

IBEX 2011 Preview

The world’s largest exhibition for the boatbuilding industry sets sail inland again, on the Ohio River. Destination: Louisville.

-

WINDPOWER 2011 Report

Wind energy advocates, turbine builders and their suppliers, policy makers, and a growing number of wind-involved composites professionals gather where it all began.

-

HHS styrene ruling: Bad science, bad for the composites industry

Tom Hedger, president of Magnum Venus Plastech (Clearwater, Fla.) and a board member of the the American Composites Manufacturers Assn. (ACMA, Arlington, Va.) joins the chorus of disapprovval that has greeted U.S Health and Human Services Secretary Kathleen Sebelius' approval of styrene's classification as a likely carcinogen.

-

Automating swimming pool production

Small producer ramps up productivity with "entry level" robotics.

-

COMPOSITES 2011 Product Showcase

Composite Technology magazine's review of the goings-on at COMPOSITES 2011, this year’s edition of the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) annual trade show and conference (Feb. 2-4, Greater Ft. Lauderdale Convention Center, Fla.).

-

IBEX 2010: Looking up in Louisville

A new location helps regenerate a recession-battered industry, drawing in more exhibitors and attendees than in 2009.

-

Preview: Composites 2011

The annual ACMA event returns to Florida, with a keynote look at composites from a military point of view.

-

IBEX 2010 Highlights

The world’s largest watercraft construction exhibition navigates new waters to its first inland rendezvous.

-

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

-

IBEX 2009 Marine Composites Showcase

The 19th International BoatBuilders’ Exhibition & Conference endures the economic “perfect storm” on the Florida coast and looks forward to fairer weather inland.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

COMPOSITES+POLYCON 2009 Showcase

Despite the deepening recession, composites pros returned to the show in its new time slot to explore the wealth of products and services collected here.

-

IBEX 2008 postshow review

Despite a sluggish boatbuilding market, this annual Miami marine showcase was the platform for the introduction of innovative composite products.

-

Composites Polycon 2007 Showcase

Tampa show attendance is up despite slow economy. ACMA reschedules 2008 show.

-

JEC Composites 2007 Product Showcase

This year’s Parisian exhibition provides key evidence of the composites industry’s unprecedented breadth and technical sophistication.

-

Meter, Mix Dispense Update

New technologies are improving accuracy, ease of use and repeatability while moving toward automation.

-

A Filament Winder Buyer's Guide

Specifying that new machine with your process and product in mind.

-

Tooling roundup: New materials, new methods

"Ingenuity" describes new tooling approaches for composites manufacturing.