NASA selects Sierra Nevada for Space Station Cargo transport contract

These Commercial Resupply Services (CRS-2) contracts are designed to obtain cargo delivery services to the space station, disposal of unneeded cargo, and the return of research samples and other cargo from the station back to NASA.

Sierra Nevada (Louisville, CO, US) was recently awarded a contract from NASA to launch cargo resupply missions to the International Space Station (ISS). This news is seen as a win for a company that had lost out on a NASA contract to transport U.S. astronauts to and from the ISS. Sierra Nevada joins Orbital ATK (Dulles, VA, US) and SpaceX (Hawthorne, CA, US) to continue building on the initial resupply partnerships.

These Commercial Resupply Services (CRS-2) contracts are designed to obtain cargo delivery services to the space station, disposal of unneeded cargo, and the return of research samples and other cargo from the station back to NASA.

While the maximum potential value of all contracts is $14 billion from 2016 through 2024, NASA will order missions, as needed, and the total prices paid under the contract will depend on which mission types are ordered.

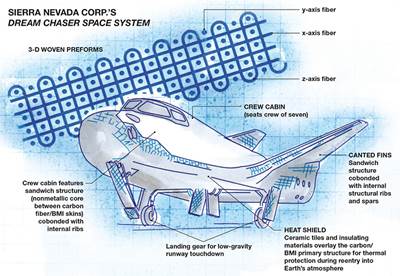

Sierra Nevada has developed the composites-intensive Dream Chaser spacecraft that has the ability to land horizontally on a runway.

The contracts, which begin upon award, guarantee a minimum of six cargo resupply missions from each provider. The contracts also include funding ISS integration, flight support equipment, special tasks and studies, and NASA requirement changes.

Selecting multiple providers assures access to ISS so crew members can continue to conduct the vital research of the National Lab. Awarding multiple contracts provides more options and reduces risk through a variety of launch options and mission types, providing the ISS program a robust portfolio of cargo services that will be necessary to maximize the utility of the station.

NASA has not yet ordered any missions, but will make a total of six selections from each menu of mission options at fixed prices, as needed. Each task order has milestones with specified amounts and performance dates. Each mission requires complex preparation and several years of lead time. Discussions and engineering assessments will begin soon, leading to integration activities later this year to ensure all space station requirements are met, with the first missions beginning in late 2019.

“These resupply flights will be conducted in parallel with our Commercial Crew Program providers’ flights that enable addition of a seventh astronaut to the International Space Station. This will double the amount of crew time to conduct research,” said Julie Robinson, chief scientist for the ISS Program. “These missions will be vital for delivering the experiments and investigations that will enable NASA and our partners to continue this important research.”

The agency applied knowledge gained from the first commercial resupply contracts with Orbital ATK and SpaceX and required a number of key enhancements for these contracts. This includes starting with a requirement for a minimum of six missions as opposed to delivery of metric tons; a variety of delivery, return and disposal capabilities for both pressurized and unpressurized cargo, as well as an optional accelerated return; and the addition of an insurance requirement to cover damage to government property during launch services, reentry services or transportation to, from, in proximity of, or docking with the space station.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

U.S. crew and cargo candidate takes shape with composites

Crew-capable Dream Chaser to enable ISS transport missions from U.S.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)