NCC announces life cycle assessment software results for construction

Study is undertaken to better understand LCA software tools to inform composites design and product development in decarbonization initiatives.

The National Composites Centre (NCC, Bristol, U.K.) has completed an assessment of the composites data referenced in software tools for life cycle assessments (LCA) used within the construction sector.

As the market looks to capitalize on the decarbonization benefits that composite materials might bring to projects, there is an increasing need to account appropriately for composite materials in the assessment tools for carbon accounting. Software and other related tools for LCA range from specific software with comprehensive life cycle inventory databases, to solutions specific to the construction sector or other applications that use composite materials.

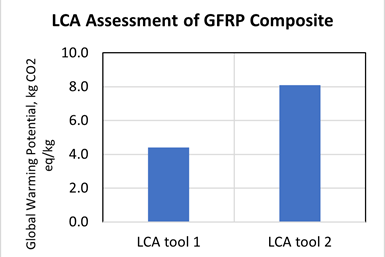

In the study undertaken by the NCC, it was found that the carbon footprint of a glass fiber composite output from one LCA software tool could be almost double for the same assessment used in another. The result is that when applied in a decision-making process in early design stages, these diverse values can force a different outcome depending on the software solution that is used.

For example, when comparing a glass fiber-reinforced plastic (GFRP) composite component to galvanized steel with a requirement to select the design with the lowest carbon footprint, the value from LCA tool 1 would indicate a lower carbon footprint and the value from LCA tool 2 would indicate a higher carbon footprint. The NCC undertake data quality assessment to determine applicability of data values, and in this case found that the value from LCA tool 1 to be more valid.

“It is crucial for users of LCA software to understand the background data referenced by these tools, in order for them to have confidence in their decisions driven by the output of assessments, and to mitigate business risk,” Ffion Martin, engineering capability lead for sustainability at the NCC says.

Global warming potential in kilogram CO2 equivalent for 1 kilogram of glass fiber0reinforced composite material. Photo Credit: National Composites Centre

Malcolm Forsyth, sustainability manager, Composites UK and Lee Canning, chair of the Construction Sector Sustainability Subteam, Composites UK note that the use of carbon emission data is now well-established as a key criteria for material selection in the construction and other major sectors. Therefore, it is vital that widely used carbon databases have up-to-date and accurate data for all materials to ensure valid and appropriate decision-making.

The NCC, together with the researchers at the University of Bath (U.K.) through the Innovation Centre for Applied Sustainable Technologies (ICAST) are establishing and applying methods for data quality assessment and presentation of uncertainty, as part of the ICAST Core Research Programme that focuses on using sustainable materials engineering to inform design and product development for decarbonization. The ICAST project will continue the LCA assessment work undertaken by NCC, and further develop LCA data for construction and infrastructure (C&I), with a focus on biomaterials and other sustainable advanced material options (e.g., glass, basalt fibers). Phase 1 of the project will complete in March 2023, which will review and implement approaches to enable users of environmental impact data to have confidence in the numbers driving carbon footprint assessment and ultimately driving design choices.

Related Content

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreSinonus launches energy-storing carbon fiber

Swedish deep-tech startup Sinonus is launching an energy-storing composite material to produce efficient structural batteries, IoT devices, drones, computers, larger vehicles and airplanes.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreSyensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

Read MoreRead Next

NCC announces Crown Estate Scotland, Owens Corning and TotalEnergies to join SusWIND

Leading stakeholders will add their voices to the SusWIND community in order to deliver a sustainable future for composites in wind.

Read MoreTeijin introduces LCA for carbon fiber intermediate materials

Life cycle assessment (LCA) studies calculate the environmental impact of Teijin composites for future emission reduction activities.

Read MoreHeartland completes first industrial hemp fiber life cycle assessment

Life cycle assessment (LCA) studies Heartland’s Imperium Filler natural fiber additive as a carbon-negative replacement for mineral fillers commonly used in plastics.

Read More