New research developments identify new methods for bio-derived carbon filler reinforcement for biocomposites

Sustainable methodologies employed by researchers from Tuskegee University enable the synthesis of carbon from biomass-based precursor materials, and its effective reinforcement in composites.

Earlier in 2022, Zaheeruddin Mohammed, a graduate from the Department of Materials Science & Engineering at the Tuskegee University (Ala., U.S.), co-published new developments in more sustainable methodologies for effective biocomposite reinforcement. Specifically, the research details a method for making higher quality bio-derived carbon (called “biochar”) to be used to reinforce polymers in 3D printing applications.

Carbon-based nanomaterials such as fullerene, carbon nanotubes (CNTs), carbon nanofibers (CNFs), graphene nanoplatelets (GNPs) and carbon black are reinforcement filler materials that have been widely used to improve or enhance the mechanical properties of composite materials. However, they are traditionally derived from fossil fuel gases/liquids like methane, ethylene and acetylene, and require expensive and sophisticated processes to be manufactured [1].

Biochar, the synthesis of carbon from sustainable biomass-based precursor materials, is said to be a bio-based alternative to these more traditional carbon nanomaterials. In addition to a more sustainable and controlled processing method, biochar carbon still effectively enables excellent mechanical and thermal properties when used as a reinforcement filler; when it comes to thermoplastics in particular, it is noted that “biochar has a competitive advantage over other natural fillers, as they are more thermally stable to the heat induced during manufacturing processes like melt blending and extrusion [2].”

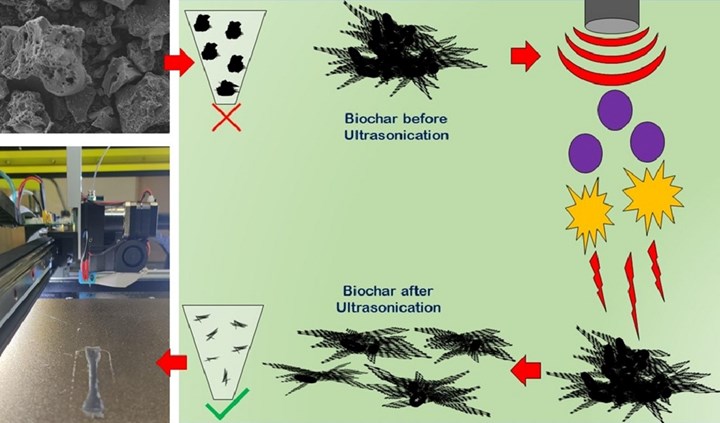

Photo Credit: Reprinted from Composites Part C: Open Access, Vol 7, 2022, 100221, Zaheeruddin Mohammed, Shaik Jeelani, Vijaya Rangari, “Effective reinforcement of engineered sustainable biochar carbon for 3D printed polypropylene biocomposites”

Nevertheless, current biochar is not as effective in improving mechanical and electrical properties of composites at low loading percentages as fossil fuel-based carbon nanomaterials; as a result high loading percentages of biochar carbons are required. To make biochar more competitive, researchers at the Tuskegee University synthesized high-quality biochar from sustainable starch-based packaging waste using a high-temperature/pressure pyrolysis reaction.

According to Mohammed et al, an ultrasonication method to reduce the particle sizes and increase active surface area was used, making biochar more compatible for dispersion, effective reinforcement and 3D printing. The modified biochar was used as an effective reinforcement filler with polypropylene polymer at a relatively low loading of 0–1 wt.%. In addition, tensile modulus and strength increased by 34% and 46% respectively with a loading of just 0.75 wt.%. Thermal stability of the composite material also improved by 51ºC in onset of decomposition temperature and 40ºC in maximum rate of decomposition temperature at 0.75 wt.%. Failure analysis of fractured surface revealed that ultrasonicated biochar was effective in reinforcing the material due to improved available surface area and nanosize defects formed on the surface of biochar carbon.

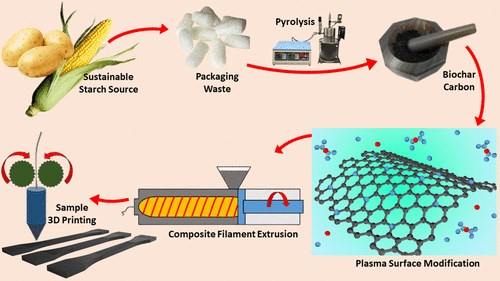

Photo Credit: Reprinted from ACS Omega, Vol 7, 2022, 39636–39647, Zaheeruddin Mohammed, Shaik Jeelani, Vijaya Rangari, “Effect of Low-Temperature Plasma Treatment on Starch-Based Biochar and Its Reinforcement for Three-Dimensional Printed Polypropylene Biocomposites”

The next challenge was achieving a good interface between the filler and the matrix. Instead of traditional wet methods for surface modification, Mohammed and his team employed low-temperature plasma (LTP) treatments in the presence of sulfur hexafluoride (SF6) gas. Ultimately, the technology was effective in the fluorination of biochar carbon like in wet chemical methods, improving tensile strength by 91% when compared to neat polymers and 31% compared to untreated biochar-reinforced polymers at 0.75 wt.% loadings. Elongation at break also increased from 12.7 to 38.78, showing a 216% increase. In this work, it was shown that plasma-based treatments were an effective and sustainable path to develop composite parts using additive manufacturing methods with improved mechanical and thermal properties [3].

References

[1] Mohammed, Zaheeruddin, Shaik Jeelani, and Vijaya Rangari. “Low temperature plasma treatment of rice husk derived hybrid silica/carbon biochar using different gas sources.” Materials Letters 292 (2021): 129678.

[2] Mohammed, Zaheeruddin, Shaik Jeelani, and Vijaya Rangari. “Effective reinforcement of engineered sustainable biochar carbon for 3D printed polypropylene biocomposites.” Composites Part C: Open Access 7 (2022): 100221.

[3] Mohammed, Zaheeruddin, Shaik Jeelani, and Vijaya K. Rangari. “Effect of Low-Temperature Plasma Treatment on Starch-Based Biochar and Its Reinforcement for Three-Dimensional Printed Polypropylene Biocomposites.” ACS Omega (2022).

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More