NIAR seeks industry experts for new digital twins study

Advanced Robotics for Manufacturing (ARM) Institute is seeking representatives to assess technology gaps related to virtual commissioning and creation of digital twins.

The Advanced Robotics for Manufacturing (ARM) Institute, an ecosystem of nearly 400 member organizations across industry, government and academia catalyzing critically needed robotics and workforce innovations in manufacturing, has selected a new joint short-cycle project from Wichita State University’s (WSU) National Institute for Aviation Research (NIAR) and Spirit AeroSystems (Wichita, Kan., U.S.) for a $400,000 award.

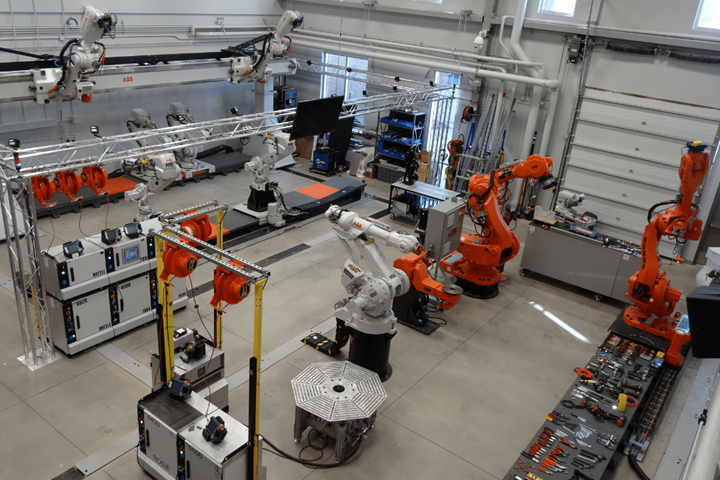

The project, titled “Technology Assessment of Virtual Commissioning for Day One Manufacturing Readiness,” involves the development of digital twins for complex manufacturing systems to reduce costs, errors and hazards that may not be apparent in the design phase.

Simulating systems by using digital/virtual twins enables system testing in a digital environment prior to installation for more successful installs and better “day one” experiences. NIAR researchers will create a report detailing the framework for the creation of a virtual twin for commissioning, and all of the steps involved in its development. The framework package will contain the data and considerations needed to develop a full digital twin.

“The NIAR team’s extensive experience with utilizing digital twins for end-to- end digital engineering, along with our expert steering committee, will be pivotal in assisting the industry’s continued adoption of virtual commissioning,” says Jeswin Joseph C., NIAR program manager and associate director of emerging technologies.

NIAR is seeking representatives for the expert steering committee. This committee will assess technology gaps in virtual commissioning and the creation of digital twins for physical robotic/automation cells, defining and guiding the use of virtual commissioning in advanced manufacturing for the next 5-10 years. To contribute, visit this link.

ARM Institute projects are selected from Project Calls. These Project Calls are crafted in collaboration with the ARM Institute’s internal team of experts, ARM members, and Department of Defense (DOD) collaborators. The 23-01 Technology Project Call specifically called for proposals to address topic areas including automated robotic task planning; multi-robot, multi-human collaboration, task sharing and task allocation; safe and scalable manufacturing of energetics; artificial intelligence (AI) in robotics for manufacturing; and discovery workshops and market studies.

Related Content

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

-

Aerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.