Plataine launches free trial package for Composites Freezer Management software

Composites fabricators can now gain better control and visibility into freezer inventory and monitoring shelf-life. With the free trial, advanced manufacturers will be able to experience the Smart Factory with no upfront cost and zero disruption to production.

Photo Credit: Plataine

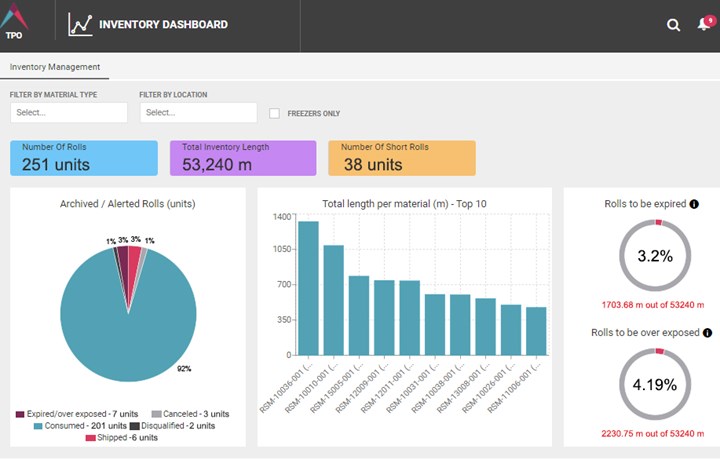

Plataine (Waltham, Mass., U.S.) announced on Oct. 29 the release of a free trial package of its Freezer Manager software application for managing factory inventory. The application is said to provide enhanced visibility and real-time tracking of time-sensitive factory inventory, while managing material quantities, shelf-life and exposure time to improve quality, increase yields and improve production visibility.

With traditional implementation practices made challenging with travel restrictions, Plataine says its Industry 4.0 solutions are cloud-based, enabling remote deployments with zero disruption to production. Specificially, Plataine launched its Freezer Manager free trial with composite manufacturers in mind, to help maximize material utilization and minimize waste and re-work. Trial users will be able to get a first-hand experience of how a smart factory feels like, which includes:

- Full material and inventory management

- Material shelf life and exposure are automatically managed by the software without manual intervention

- Up-to-date inventory dashboards that provide complete and accurate visibility of inventory levels.

The Freezer Manager which is part of Plataine’s TPO (Total Production Optimization) solution suite, additionally offers AI- and IoT-based “Digital Assistants” that complement existing systems and deliver smart alerts and recommendations in real-time to digitize, automate and optimize manufacturing processes.

"Plataine is committed to help spearhead Smart Factory initiatives worldwide. Our cloud architecture and product maturity allow our customers to test-drive AI and IoT capabilities at no cost, nor disruption to their daily work,” says Avner Ben-Bassat, president and CEO of Plataine. “With our first verticalized trial offering, composites fabricators can now gain better control and visibility into freezer inventory and monitoring shelf-life and have a direct impact on manufacturing costs and bottom lines.”

Related Content

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

ST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

-

New Frontier Technologies launches digital twinning, high-fidelity simulation capability

3D imaging and analysis capability illustrates detailed, quality characterization and performance simulation of composites and other advanced materials that properly captures the as-manufactured component.