Purdue-related startup Araqev creates quality-control software for additive manufacturing

Araqev software expected to help reduce estimated $2 billion in global losses when using AM through machine learning models that simulate shape deviations for future prints.

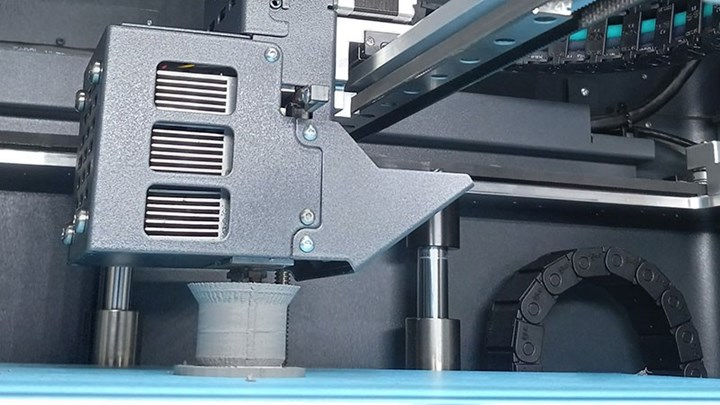

A Markforged Metal X 3D printer creates a stainless steel tool in Purdue University's Herbert C. Brown Laboratory of Chemistry. Photo Credit: Purdue Research Foundation photo/Steve Martin

Araqev, a Purdue University-related (West Lafayette, Ind., U.S.) startup company, has commercialized quality-control software for additive manufacturing (AM) and 3D printing processes.

Araqev’s software is reported to help end users print products in only a few design iterations, leading to less scrap material and machining time, eliminating the frustrations with 3D printing and improving satisfaction with the final printed products. Arman Sabbaghi, associate professor in Purdue’s Department of Statistics in the College of Science, is Araqev’s CEO and president.

“We estimate that the quality-control issue with AM can lead to nearly $2 billion in global losses annually based on a model for the production costs of metal AM systems that was developed by Baumers, Dickens, Tuck and Hague in their 2016 paper published in the peer-reviewed journal Technological Forecasting and Social Change,” Sabbaghi says.

To use Araqev’s software, customers upload their nominal design files and scanned point cloud data from their printed products.

“Our software uses these inputs to fit machine learning [ML] models that can simulate shape deviations for future printed products,” Sabbaghi says. “Furthermore, the ML models enable our software to derive modifications to the nominal designs, known as compensation plans, so that when the modified designs are printed, they will exhibit fewer shape deviations compared to the case when the original designs are printed.”

Araqev’s algorithms also enable the transfer of knowledge encoded via ML models across different materials, printers and shapes in an AM system, Sabbaghi points out. “This means that our software enables a comprehensive platform for a customer to improve quality for their entire system.”

“The power and cost-effectiveness of our algorithms were most recently demonstrated via two validation experiments for the Markforged [Cambridge, Mass., U.S.] Metal X 3D printer involving 17-4 PH stainless steel products,” Sabbaghi says. “Our algorithms reduced shape inaccuracies by 30-60%, depending on the geometry in at most two iterations, with three training shapes and one or two test shapes for a specific geometry involved across the iterations.”

Araqev is establishing direct partnerships with 3D printing manufacturers and companies using 3D printers that Sabbaghi says will enable the company to scale quickly. “We will establish licensing contracts after demonstrating to the companies the savings and benefits that we can offer for their processes,” he adds. “These partners will incorporate our software into their systems and sell them to their customers, which provides us with a significant customer channel.”

Araqev licensed the software from the Purdue Research Foundation Office of Technology Commercialization. The research to create the software received funding from the NSF's Cyber-Physical Systems program and CMMI EAGER program, and the Purdue Research Foundation Office of Technology Commercialization’s Trask Innovation Fund. Araqev received funds from Elevate Ventures' Regional Pre-Seed Competition, Purdue's Regional NSF I-Corps program, the MKE Tech Hub Coalition Challenge and the Purdue Foundry Boost program.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

.jpg;maxWidth=300;quality=90)