RATH prepares for production of advanced oxide ceramic fiber for CMC

New facility in Germany is part of regional supply chain and vision to lead green energy transition using CMC, supported by German government and Composites United’s Ceramic Composites network.

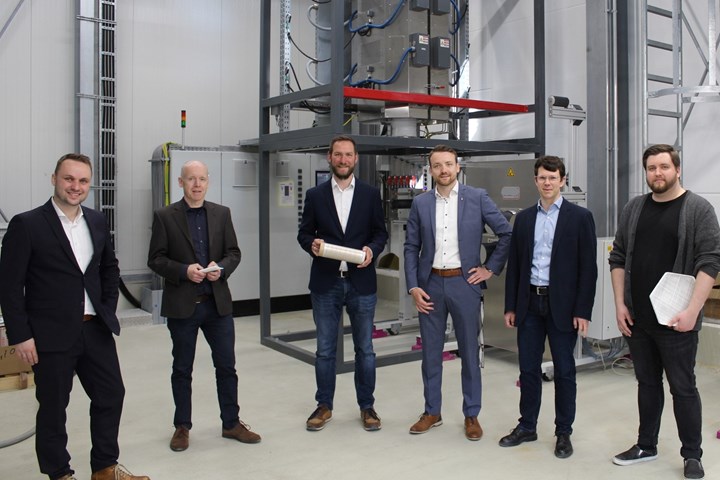

RATH advances as new source for oxide fiber in CMC materials. Michael Roth, German state parliament candidate, can be seen holding a spool of oxide fiber at RATH site in Mönchengladbach, Germany. From left to right: Denny Schüppel (Composites United), Dr. Peter Mechich (DLR), state parliament candidate Michael Roth and from RATH: Christopher Kluthe, Dr. Philipp Franja and Cedric Dreyszas.

For more than 125 years, the RATH Group (Vienna, Austria) has combined materials expertise, application know-how and personal consulting to provide high-temperature materials for unique applications. It is now breaking ground for a new facility in Mönchengladbach, Germany where RATH is developing a high-end oxide ceramic fiber, a key component for the production of fiber-reinforced ceramics known as ceramic matrix composites (CMC).

This market has been dominated by only one American fiber manufacturer. RATH seeks to change that, because broad use of these high-tech materials promises to make the green energy transition more efficient and ecological. “Wherever lightweight design meets high temperatures, we need CMC materials,” Christopher Kluthe says, responsible for ceramic continuous fibers in the Rath Group. “Fiber composite ceramics are based on the broad market availability of oxide ceramic fibers. Only in this way will these technologies be able to make their contribution to the energy transition.”

On May 3, key representatives from industry and research met with German state parliament candidate Michael Roth at RATH GmbH in Mönchengladbach to jointly discuss new technologies for the energy transition. In addition to Kluthe, this meeting was attended by Dr. Philipp Frania, plant manager for RATH; Dr. Peter Mechnich, co-department head at the DLR Institute for Materials Research in Cologne, Germany and Denny Schüppel, managing director of Ceramic Composites, said to be the world’s largest specialist network for ceramic composites, which has been formed within the German composites association, Composites United e. V. (Berlin).

Participants in the May meeting at Mönchengladbach learned about the new material to be produced there and the new possibilities it offers. “Technologically disruptive leap innovations are what the country needs to retain industrial jobs and drive green energy supply,” German parliament candidate Roth said. “It's great that small- and medium-sized businesses in my home country can contribute to this. I am happy to support RATH in this effort.”

With the closely meshed network of research and industry, the North Rhine-Westphalia (NRW) region where RATH Mönchengladbach is located, can become Evoa pioneer in the energy transition. Strong partners from research, such as the German Aerospace Center (DLR) and the Jülich Research Center (Jülich, Germany) — which is a member of the Helmholtz Association of German Research Centers, one of the largest interdisciplinary research centers in Europe — are reported to be just as active as small and large companies. From component manufacturers, such as WPX fiber ceramics (Bonn, Germany), to quality assurance at Diondo (Hattingen), to users such as Ford (Cologne), Linde (Lindlar) and Evonik (Essen), the partners in the NRW region represent the entire value network and are positioning themselves as pioneers of the energy transition.

“Especially the generation of green hydrogen is currently still accompanied by high energy losses. We want to improve that significantly in the future. The green energy transition needs CMC.” — Denny Schüppel, managing director, Ceramic Composites network

“Especially the close cooperation between industry, SMEs and research predestines the region and the network to develop innovative solutions from CMC quickly and in a target-oriented manner,” Mechnich from DLR says. He himself has been conducting research at the DLR Institute for Materials Research in Cologne for more than 20 years. “Reliable, regional supply chains pave the way for innovative technologies and products.” Whether these are technologies for saving energy, or for generating or converting green hydrogen into electricity, “the energy transition needs CMC and we care about helping here,” Schüppel of Composites United notes. “Especially the generation of green hydrogen is currently still accompanied by high energy losses. We want to improve that significantly in the future."

The first components with RATH fibers have already been manufactured. Work is underway in an EU project to compete with the current global players, and soon it will be said: Companies and research institutions in NRW are taking a leading role for technologies of the energy transition.

Related Content

Bombardier begins manufacture of Global 8000 business jet

Ultra-long range business jet featuring CMC-intensive engine and a range of 8,000 nautical miles is set to enter service in second half of 2025 as it remains on track for flight testing.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreDeveloping milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

Read MoreMATECH C/ZrOC composite is deployed in hypersonic aeroshells

Ultra high-temperature insulating CMC targets hypersonics, space heat shields and other demanding applications, tested up to 2760°C under extreme stagnation pressures.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More