Revolution Fibres rebrands to NanoLayr

Nanofiber manufacture rebranding reflects large-scale expansion, sets platform for future growth and innovation for high-performance functional textiles.

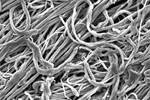

NanoLayr sonic electrospinning process. Photo Credit: NanoLayr

New Zealand-based nanofiber manufacturer, Revolution Fibres (Auckland) has rebranded to NanoLayr to reflect its transformation into a deep tech manufacturer and a global leader in high-performance functional textiles.

Founded in 2009, the company is known for its advanced nanofiber technology using a proprietary sonic electrospinning process, which introduces drops of a polymer solution to a high voltage field to manufacture nanofiber products, including filter media for N95 and N99 face masks and collagen skincare product ActivLayr.

CEO Ray Connor says the rebrand to NanoLayr sets a platform for future innovation and the continued manufacture of nanofiber solutions that provide a competitive edge for its customers as well as benefiting society.

“An increasing number of industries are embracing what nanofiber can do to make products better and stronger, to maximize performance and establish that competitive advantage,” Connor says. “NanoLayr’s sonic electrospinning technology can lead the world in the production of nanofiber. Our focus is to maximize the potential of our platform technology in a way that we can make a positive impact on the lives of as many people as possible.”

The rebrand follows a 12-month period where the company underwent significant expansion. It moved into a new factory over 20 times the size of its old facility and upscaled to meet global demand for nanofiber solutions across a wide range of sectors, including filter media, skincare and sound insulation for the construction and furniture industries.

“The new factory quadruples our capacity and strengthens our capability to manufacture quality functional nanofiber textiles on a vast scale to meet ongoing international and local demand,” says Connor.

NanoLayr’s new 5,500-square-meter facility is home to five customized sonic electrospinning machines that are said to manufacture nanofiber rolls thousands of meters long for export to markets such as Asia, Australia and the U.S. The factory, says Connor, also has significant capacity for future growth.

“A single kilogram of raw material can produce enough nanofiber strands that, when placed end on end, can reach from Earth to Venus — that’s 253 million kilometers,” he notes.

With NanoLayr adopted as the company name, product names and branding has also changed to reinforce the Layr brand, including:

- FilterLayr: SETA nanofiber filter media changes to FilterLayr to highlight its application across a range of air filtration products and systems from facemasks that meet N95 and N99 standards through to ventilation systems.

- SonoLayr: Phonix rebrands to SonoLayr which uses electro-spun nanofibers with high permeability and absorbency to create what NanoLayr says are the thinnest acoustic veils.

- DermaLayr: DermaLayr will be positioned as a premium bioactive nanofiber technology delivery platform. To support ActivLayr’s strong brand recognition as a collagen skincare brand it will be reinforced by a new platform brand, DermaLayr.

- XantuLayr: The composite-strengthening nanofiber product, which retains its original name, improves impact resistance, flexural strength and fatigue life of composite it is used on products.