Rolls Royce launches Pearl family of engines

The Pearl 15 is the first of the planned Rolls-Royce’s Pearl engine family, which will be used for Bombardier’s Global 5500 and Global 6500 business jets.

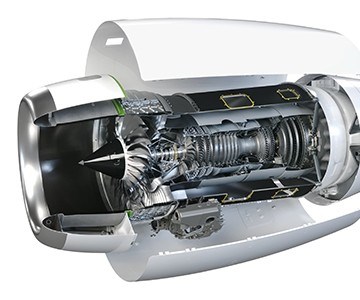

Rolls-Royce (London, UK) announced on May 28 the launch of a new engine family for business aviation, with the introduction of the Pearl. The engine will be used for Bombardier’s latest business jets, the Global 5500 aircraft and the Global 6500 aircraft. The Pearl 15 is the first of the planned Pearl engine family for business aviation and marks the sixth new civil aerospace engine introduced by Rolls-Royce in the past 10 years.

The Pearl engine combines technologies derived from Rolls-Royce’s Advance2 technology demonstrator programmes with proven features from the Rolls-Royce BR700 business aviation engine family. The engine employs composite materials for the engine’s bypass duct, the nacelle and the brand-new hybrid light-weight drive shaft. The composite drive shaft is a key enabler for the new high-speed core engine and has been developed in cooperation with Rolls-Royce’s global University Technology Network (Dresden, Germany and Bristol, UK).

The new engine, which was developed at Rolls-Royce’s Centre of Excellence for Business Aviation engines in Dahlewitz, Germany, received EASA certification on Feb. 28. The engine is currently undergoing flight tests at Bombardier’s Flight Test Centre in Wichita, KS, US and has a planned entry into service at the end of 2019.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.