Rolls-Royce Power Systems, Porterbrook work together to develop hydrogen in rail for U.K.

Multiple developments are aimed to support government goal to remove diesel-only trains by 2040 and achieve net-zero rail by 2050.

Photo Credit: Rolls-Royce, Porterbrook

Rolls-Royce (London, U.K.) have signed a memorandum of understanding (MOU) with U.K. rail rolling stock owner and asset manager Porterbrook (Derby, England), to identify and develop technological innovations to reduce carbon emissions and improve air quality across the rail network. The two companies will investigate the potential for the use of synthetic and net-zero fuels, including hydrogen, both in fuel cells and internal combustion engines, of which it can be assumed composite materials will most likely play a role (see “Hydrogen is poised to fuel composites growth, Part 1” and Part 2). Building on recent success of jointly introducing hybrid battery-diesel railcars into passenger service, Rolls-Royce and Porterbrook will also explore the potential for advanced hybridization.

The role of the wider rail ecosystem in decarbonization, including fuel chain supply, infrastructure and operational models that can aid innovation and the transition to net zero will also be considered.

“We have extensive experience of rail technology and are able to draw upon expertise from across our business in new net-zero and zero emissions technologies for safety-critical applications,” Warren East, CEO, Rolls-Royce says. “We are committed to helping our customers make the transition to net zero by enabling them to use our current and future products in a way that is compatible with emissions reduction, and this relationship with Porterbrook will help us further understand the options for decarbonizing rail transport. For us, playing a leading role in enabling the energy transition is both a societal imperative and a significant commercial opportunity.”

U.K. railway accounts for approximately 1% of all domestic greenhouse gas (GHG) emissions (according to 2019 figures. UK Department for Transport: Decarbonising Transport, 2021) and the Government’s ambition is to remove all diesel-only trains — both passenger and freight — from the network by 2040 and achieve a net-zero rail network by 2050. The UK Government has identified a number of different routes to this target, including alternative forms of power such as hydrogen, fuel cells, batteries, hybrid-electric and sustainable fuels.

“We have been at the forefront of developing alternative traction systems for rolling stock over recent years, through our innovations and long-term asset management approach. Our partnership with Rolls-Royce will mean that we continue to lead the U.K.’s rail sector in sustainable solutions, by leveraging expertise across industries on the pathway to net zero,” adds Porterbrook CEO Mary Grant.

Rolls-Royce Power Systems has been active in this field, having already developed the hybrid-electric mtu Hybrid PowerPack, which recently entered commercial service in the U.K. with Chiltern Railways (U.K.) on HybridFLEX trains. Supplier by Porterbrook, the technology is said to reduce CO2 emissions by up to 25%.

Power Systems is currently developing a range of engines that can run on hydrogen, and fuel cells to be used as reliable power supply in ships and heavy-duty, off-highway vehicles. In 2021, Power Systems committed to release new generations of its most popular diesel engines — including the mtu Series 4000 engines — for use with sustainable fuels by 2023. From next year it plans to have conversion kits available to enable mtu Series 4000 engines to run on 100% hydrogen.

Porterbrook has an established reputation for delivering new technologies, such as battery, hybrid and hydrogen powered trains. Alongside the HybridFLEX and other hybrid trains in commercial service, the company has developed HydroFLEX, reported to be the first hydrogen-powered train to run on the U.K.’s mainline network. It can operate under electric, battery and hydrogen power.

Related Content

Polar Technology develops innovative solutions for hydrogen storage

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

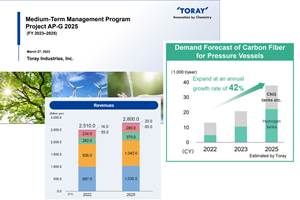

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More