Roth Composites Machinery delivers customized filament winding system

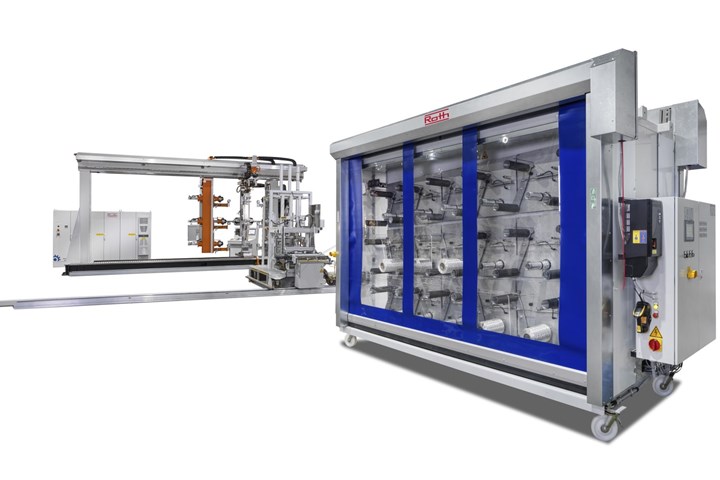

Three-spindle system for the manufacture of hydrogen tanks boasts a flexible impregnation station and enhanced automation with a 40% increase in performance.

Photo Credit: Roth Composites Machinery.

Roth Composite Machinery GmbH (Steffenburg, Germany) has recently delivered a customized filament winding system for the manufacture of hydrogen tanks with three spindles.

“A high-performance drive concept combined with a new machine frame structure enable performance improvements of about 40% compared to the international state of the art,” says Dr. Andreas Reimann, general manager of Roth Composite Machinery,

The machine concept comprises five interpolating axes and five additional CNC programmable axes. Roth Composite Machinery says the machine’s setup is suitable for series production as well as for development applications (R&D) using the traditional wet winding process.

A movable impregnation station, suitable for carbon and glass fiber processing, enables the use of individual, single spindles in order to avoid unnecessary resin consumption. An NC-controlled doctor blade allows a precise and reproducible adjustment of the resin gap. Decreased wrap angles reportedly reduce roving load, and by means of double cylinder control and the fiber storage device, the company says even very low fiber tensions can be adjusted in line with the process. Consistent fiber delivery speeds of up to 4.5 meters per second are possible.

Further, the production line is said to be prepared for a quick and easy change to towpreg winding, and through the use of the ROTH RCA (automatic roving cutting and applying device), the automation level of the machine has been increased.

Emphasizing the filament winding line’s capabilities, Roth Composites Machinery gives the example of winding of pressure vessels. The machine is equipped with an automatic pressurization and pressure measuring system which is able to create and regulate the necessary inner pressure of the liner during the winding process, the company says. Exceptional machine stiffness further minimizes mechanic impact on the manufacturing process and ensures high precision during the filament winding process.

Related Content

-

McClarin Composites partners with ExxonMobil to accelerate high-speed RTM

Multimillion-dollar investment to drive next-gen automated RTM technology will open new applications and markets for composites OEMs.

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.