RUAG International sells aerostructures business, grows Beyond Gravity space business by 8% in 2023

Beyond Gravity is expanding and modernizing sites, adding AFP and a new facility in Decatur to double capacity.

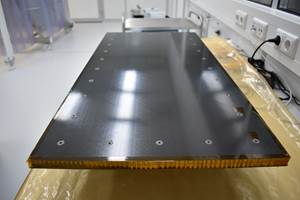

Beyond Gravity produces payload fairings at its sites in Decatur, Alabama, and Emmen, Switzerland. Source (All Images) | RUAG International

In 2023, RUAG International (Bern, Switzerland) transformed itself into a space market-focused international supplier by selling its aerostructures business. The financial year was characterized by an inflationary market environment and strained supply chains. At the same time, investments were made in the expansion of production and the digital future of the space business. Adjusted for divestment and foreign currency effects, sales increased by CHF 62 million (~$69.6 million) compared to the previous year. Reported earnings before interest and taxes (EBIT) amounted to CHF 28 ($31.4).

Now that RUAG has completed the privatization of its aerostructures business, the company will concentrate fully on the rapidly growing space market. André Wall, CEO of RUAG International, credits the success of the privatization in particular to the employees: “Their commitment, loyalty and excellent work have enabled us to get through this phase smoothly and to find sustainable follow-up solutions for our employees and customers. I would like to thank each and every one of them for their contribution.”

Due to substantial company divestments in 2023 and 2022 (including RUAG Ammotec), key figures can only be compared to a limited extent. However, they reflect the continuous progress of the divestment strategy adopted jointly with the owner, the Swiss Confederation. The number of employees fell accordingly from 2,963 to 1,989 worldwide. Net sales, 96% of which came from civil activities, fell to CHF 620 million/~$696.4 million (previous year CHF 945 million/~$1.1 billion) and EBIT to CHF 28 million (~$31.4 million)

(CHF 178 million/~$200 million). Adjusted for divestment and foreign currency effects, sales increased by CHF 62 million (~$70 million) compared to the previous year.

Space business is on a growth track

The Space segment (Beyond Gravity), with around 1,600 employees, increased sales by 8% to CHF 383 million (~$430 million) (previous year: CHF 356 million/~$400 million). Despite massive investments in the expansion

of production and digital infrastructure, EBIT recovered from CHF -5 million (-$5.6 million) to CHF 0 million, thus laying the foundation for profitable growth. At CHF 408 million/~$458 million (CHF 439 million/~$493 million) and CHF 729 million/~$818.8 million (CHF 744 million/~$835.6 million) respectively, order intake and order backlog remain at a high level. André Wall concludes: “Beyond Gravity can proudly point to full order books. This

underlines the company’s strong position as a key player in the global space market.”

Aerostructures business successfully sold

With the sale of the entire Aerostructures segment, all shares and around 1,000 employees of RUAG Aerostructures Germany and Hungary have been transferred to the German family-owned company Mubea, while Pilatus Aircraft Ltd. has taken over all machines and 230 employees of RUAG Aerostructures Switzerland. RUAG Aerostructures Switzerland AG will continue to exist as a company for the time being and will finalize

existing customer commitments with non-Pilatus customers. Another divestment related to the sale of the company site in Zurich-Seebach to the City of Zurich, with RUAG International leasing the site back until at least 2030.

In the Aerostructures segment, sales increased to CHF 240 million/~$270 million in 2023 (previous year: CHF 235 million/~$264 million). However, EBIT fell significantly from CHF 43 million (~$48.3 million) to CHF -17 million (-$19 million). This was caused by delays in international supply chains, changing customer requirements and production volumes as well as extraordinary expenses in connection with divestment projects. The reversal of provisions and value adjustments in 2022 must also be taken into account.

At its site in Linköping, Sweden, Beyond Gravity produces dispenser that place satellites into space.

Expanding production sites in the U.S. and Sweden

Following the major order from Amazon in 2021 for the production of satellite dispensers and launch vehicle structures for the Kuiper satellite project, production sites in Linköping (Sweden) and Decatur (U.S.) are being expanded and modernized. In Linköping, the company will rely on automatedmanufacturing processes (AFP specifically) in the new

production building. In Decatur, where payload fairings for the Vulcan Centaur launch vehicle are manufactured, a new facility with an annual production capacity of 25 payload fairings (50 half-shells) is being built. This corresponds to twice the capacity of the current plant. The opening of both plants is already planned for 2024.

Investing in the digital future

RUAG International also invested heavily in the digital transformation of its Space division during the reporting period. The “EZYone” project aims to build a strong digital core for Beyond Gravity, harmonize processes, create a solid database and implement a uniform system landscape. These measures will enable smooth collaboration across different locations, promote faster innovation cycles, reduce administrative costs and lay the foundations for the increased use of artificial intelligence, augmented reality and other forward-looking technologies.

Overall outlook

Strong growth in both the institutional and private space market is expected to continue in the coming years. With the ramp-up of the new production capacities in Decatur and Linköping, and the gradual rollout of “EZYone” from 2024, Beyond Gravity reportedly have a powerful basis for profitably capitalizing on the expected growth in the industry. Even in view of the privatization of Beyond Gravity by the end of 2025 at the latest, RUAG International’s focus remains on systematically continuing the transformation of all business areas into digitally networked and economically viable units.

Related Content

HyImpulse, Adamant Composites linerless CFRP tank passes hydrostatic burst test

The liquid oxygen (LOX) tank, to be used in a HyImpulse smallsat launch vehicle, demonstrates the ability to withstand pressures well beyond the limits of its intended use.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreAirborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

Read MoreRead Next

Siddus Space launches composites-intensive LizzieSat satellite

LizzieSat offers space-based data collection and analysis for SpaceX’s Transporter-10 Rideshare mission.

Read MoreBeyond Gravity innovates space with reusable payload fairing

Reuse of composite second stage half-shells could make rockets more accessible to various companies and support more frequent launches.

Read MoreBeyond Gravity wins contract for Ariane 6 payload fairings

Extended partnership for the 20-meter-high carbon fiber payload fairing variant manufactured at Beyond Gravity’s Emmen facility builds on decades of composite space component manufacture.

Read More