Beyond Gravity wins contract for Ariane 6 payload fairings

Extended partnership for the 20-meter-high carbon fiber payload fairing variant manufactured at Beyond Gravity’s Emmen facility builds on decades of composite space component manufacture.

Beyond Gravity (formerly RUAG Space, Zürich, Switzerland) has won an order to produce the carbon fiber payload fairings for ArianeGroup’s (Les Mureaux, France) new Ariane 6 rocket. The new European launcher replaces Ariane 5, which was successfully launched more than 100 times and has been in service since 1996.

Beyond Gravity offers two different-sized payload fairing variants that consist of two half-shells that separate once they reach orbit. Accounting for one-third of a launch vehicle’s total length and rising to the height of a six-story building, the 20-meter-high variant (A64) is said to safeguard valuable cargo on its voyage to space. The smaller version is 14 meters high. Both variants have a 5.4-meter diameter, ensuring ample room for a variety of payloads.

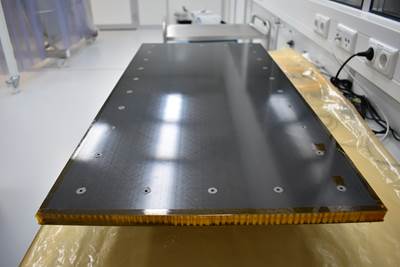

The Ariane 6 payload fairings, which are the A64 variant, are manufactured by Beyond Gravity at its Emmen site in Switzerland. In a semi-automated process, the company manufactures each half-shell in one piece from carbon fiber-reinforced composites that is “cured” in an industrial oven. This reduces costs compared with autoclave-produced half-shells and enables production to move twice as quickly. The resulting payload fairings weigh only 1.8 to 2.6 tons.

Paul Horstink, executive vice president, Beyond Gravity, notes that with the commercial market in mind, the company is also “driving future innovations, such as further shortening lead times or exploring possibilities in reusability to redefine the boundaries of space exploration.”

“Over the years, Beyond Gravity has manufactured more than 250 payload

fairings for the Ariane launcher rockets,” André Wall, CEO of Beyond Gravity, adds, noting their decades of close partnership with ArianeGroup producing payload fairings for all missions since Ariane’s first flight in 1979.

Beyond Gravity’s expertise in composite payload fairings has also won it a contract for the United Launch Alliance’s (ULA) Vulcan rockets and the European Vega-C rockets. Another contract, this time from Amazon, was awarded to the company in June 2022 for scalable carbon fiber-reinforced polymer (CFRP) dispenser systems.

“This contract with Beyond Gravity is a new and key step towards a strong Ariane 6 European team” says Stephane Nogatchewsky, EVP head of procurement at ArianeGroup. “While the inaugural flight of Ariane 6 is getting closer and the industrial ramp-up is intensifying, this collaboration is a positive and critical milestone for the future of Ariane 6 operations. Also, unifying European actors is paramount to ensure further industrial robustness, competitiveness and to preserve European autonomous access to space.”

Ariane 6, a program of the European Space Agency (ESA), is a family of launchers designed to offer maximum flexibility to customers in the institutional and commercial markets. Due to its large volume under the payload fairing, Ariane 6 can perform classic single or dual launches as well as complex missions that meet new market requirements, such as launching satellites with electric propulsion or multiple launches of constellation satellites. In addition to composite payload fairings, these launch vehicles sport an upper and lower interface structure that “is reported to be the largest carbon fiber structure for space produced in Europe. The other composite structures include the launch vehicle adapter for the upper stage, and the equipped rocket upper part of each rocket booster,” all of which are delivered under contract by Airbus (Toulouse, France).

The launcher will be available in two versions, depending on the mission: The Ariane 64 with four boosters can carry more than 12 tons into geostationary transfer orbit (GTO) with a dual launch. The Ariane 62 with two boosters can carry more than 4.5 tons of payload into GTO or seven tons into sun-synchronous orbit (SSO).

Related Content

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

Read MoreRocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MoreSyensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Plant Tour: RUAG Space, Decatur, Alabama, U.S.

Out-of-autoclave composites manufacturing facility comes of age with first U.S.-made composite structures for the Atlas V launcher, and qualification parts for the Vulcan.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More