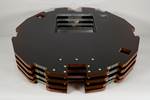

Siddus Space launches composites-intensive LizzieSat satellite

LizzieSat offers space-based data collection and analysis for SpaceX’s Transporter-10 Rideshare mission.

Sidus Space (Cape Cavaveral, Fla., U.S.) a multi-faceted space and data-as-a- service satellite company, has announced that its LizzieSat satellite has successfully launched and deployed to low Earth orbit (LEO) as part of SpaceX’s (Hawthorne, Calif., U.S.) Transporter-10 Rideshare mission. Liftoff occurred at 2:05 p.m. PDT from Space Launch Complex 4 East at Vandenberg Space Force Base in California.

LizzieSat uses Onyx FRA along with continuous carbon fiber to reinforce the satellite structure and parts. The former is a flame-retardant variant of Onyx, Markforged’s (Waltham, Mass., U.S.) 3D printing material that can be reinforced with any continuous fiber.

LizzieSat is positioned to enable space-based data collection and analysis via its Space Platform with a Purpose and FeatherEdge AI integration. This mission aims to broaden its customer base across military and commercial sectors, offering tailored intelligence solutions for industries such as defense, agriculture, maritime, and oil and gas. Sidus Space anticipates upcoming missions, with LizzieSat-2 and LizzieSat-3, expected to launch on future SpaceX Rideshare missions.

According to space.com, Transporter-10 carries “multiple smaller payloads for a large number of customers. These launches offer a convenient and more affordable way for private companies to place satellites into orbit without the needing to wait and ‘tag along’ on the launch of a larger spacecraft.”

Related Content

-

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

-

Demonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.