Stratview Research publishes new report on composites use in the AAM/eVTOL markets

The detailed thought leadership report explores the highly profitable synergy that is going to take place between the composites and the eVTOL industry in the coming years, including an analysis of 500+ eVTOL programs and inputs from 20+ industry experts.

Photo Credit: Stratview Research

Stratview Research (Detroit, Mich., U.S.), a global business intelligence and market research firm, has released a thought leadership report that explores the highly profitable synergy that is going to take place between the composites and the electric vertical takeoff and landing (eVTOL) industry.

Titled, “eVTOLs: The new ‘vertical’ for the Composites Industry,” the report aims to serve as an ideal resource for stakeholders of the eVTOL and the composites industry for investigating the potential opportunities that will come to the surface following the advent of vertical flights.

With an analysis of 500+ eVTOL programs and inputs from 20+ industry experts including eVTOL OEMs, composite part fabricators and material suppliers, the report analyzes the drivers and roadblocks in the industry in sufficient detail. According to Stratview Research, the report takes into account, several factors like funding, certification, suggested manufacturing targets, pre-orders, cost of ownership, adaptability and more, providing details on the current market along with a forecast up to 2040.

The report also discusses factors like pollution, congestion, etc. as the major drivers leading to the development of eVTOLs. A dedicated section presents an analysis of 500+ eVTOL programs and answers critical questions like:

- What percentage of the eVTOLs are purely electric and what percentage are hybrid-electric?

- Which eVTOL configuration (vectored thrust, wingless, etc.) is the most dominant, and how many programs are listed under each?

- What percentage of the programs are autonomous and/or are planning to be autonomous in the future?

Specific focus has been given to the applications of composites in eVTOLs and the depth of the discussion has been kept such that the report establishes itself as a “one of its kind” resource available on the web, on this particular subject.

The dedicated section on the applications of composites in eVTOLs brings up necessary information like the list of parts in an eVTOL that can be made out of composites, the processes that can be deployed in the manufacturing of each part and also the nature and type of the materials to be used.

Challenges like approval from the regulatory authorities, security, community acceptance, shortage of production capacity, lack of UAM-supporting infrastructure, cost of ownership, willingness to pay and more have been discussed, and experts’ opinions on what the industry needs to do in order to overcome these challenges have been presented.

Some of the key findings from the report are mentioned below:

- The eVTOL market will be valued at close to $55.7 billion in the year 2040.

- There will be more than 200,000 eVTOLs operational worldwide in the year 2040.

- As of October 2022, investments worth more than $5 billion have been made in the eVTOL industry.

- As of October 2022, the eVTOL industry combined has 6,000+ conditional pre-orders in the pipeline.

- The estimated demand for composite materials from the eVTOL industry will shoot over 1 million pounds as soon as 2025.

- North America and Europe will observe the quickest adaption of eVTOLs and will maintain their dominance till 2040

The complete report can be accessed for free in Composights, an online portal that offers free thought leadership reports, whitepapers, market report synopsis and much more for composites and allied industries, worth $20,000 every year.

The complete report can also be accessed at this link.

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreComposite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreMidnight production aircraft completes full transition flight

This is Archer’s second full-scale eVTOL aircraft to achieve this milestone, critical to being able to carry commercially viable passenger payloads.

Read MoreRead Next

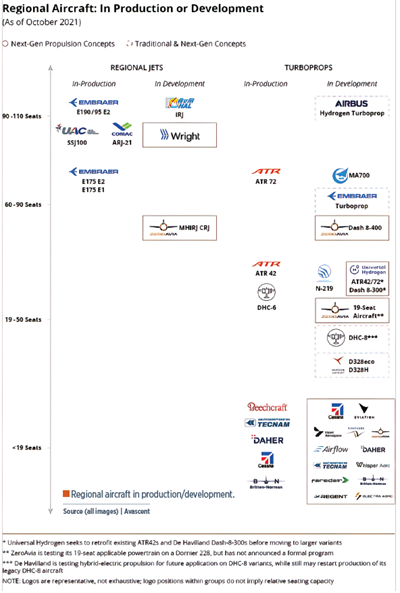

Regional air mobility: A meaningful first step in the electric aviation revolution

Electrification of fixed-wing, <50-seat regional aircraft might stimulate a new era of growth that could help pave the way for advanced air mobility (AAM) aircraft.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More