Sumitomo Bakelite eAxle demonstrator drives forward novel thermoset composite material applications

The fully functional eAxle, a single, compact unit that directly powers electric vehicles, will showcase the project’s newly developed materials and assemblies and validate efficiency improvements and increased design flexibility.

Share

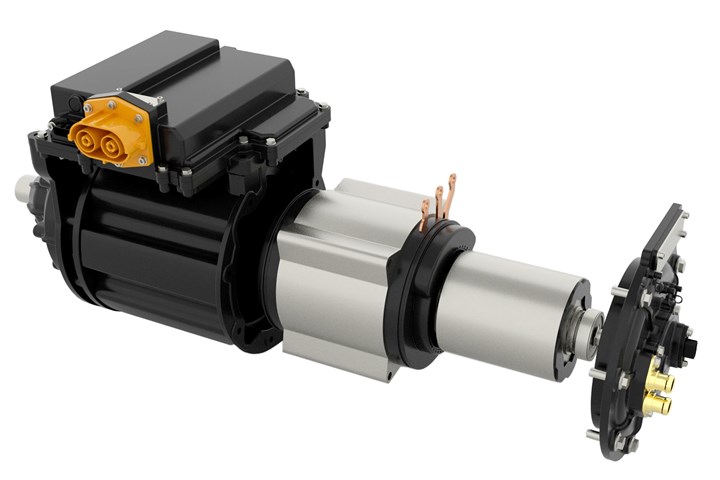

eAxle demonstrator. Photo Credit: Sumitomo Bakelite

Sumitomo Bakelite Co. Ltd (Tokyo, Japan) has announced a major research project, the eAxle Project, to accelerate the development of thermoset composite material applications in next-generation electric drivetrains.

An eAxle typically combines an electric motor, electronic power management and transmission in a single compact unit that directly powers an electric vehicle (EV). With an EV powertrain generally accounting for >30% of the vehicle’s weight, Sumitomo Bakelite says reducing this figure is key to increasing range and allowing smaller and cheaper batteries to be used.

Under this project, Sumitomo Bakelite says it will demonstrate how its high-performance plastics enable higher eAxle efficiency, improved thermal management and a reduction in both component weight and size for OEMs and Tier suppliers, within an eAxle assembly. A fully functional demonstrator unit will be delivered in 2022 that showcases the project’s newly developed materials and assemblies, which will take advatage of the company’s thermoset composite materials, to lightweight components, help the traction motor run cooler than current industry standards allow and increasing design flexibility. The manufactured demonstrator unit will feature a 150-kilowatt IPM-type electric motor and will target a highly compact final assembly with a weight of just 80 kilograms (approximately 176 pounds).

Some of the project’s early technical findings were presented at the recent Charged EV Engineering virtual conference by Jason Du, marketing manager, Sumitomo Bakelite North America Inc., where Sumitomo Bakelite detailed how its new stator encapsulation technology uses overmolded thermally conductive composite materials to replace traditional paper insulation and reduce stator temperatures. Additional developments in this critical area of the eAxle motor include enhanced cooling structures that will further advance the operating temperature reductions realized so far.

Sumitomo Bakelite’s eAxle testing and validation program will also include collaboration with leading research organizations such as the Fraunhofer Institute (Germany) and other academic institutions in Italy and France. As some of the extended test program data becomes available during the project, the company intends to provide further updates on specific performance gains, including noise, vibration and harshness (NVH) improvements realized by the replacement of metallic components with composites.

Sumitomo Bakelite will unveil its new eAxle demonstrator in late Q1 2022, showcasing a series of composite enhancements throughout the unit and clearly outlining a path for increased composite material use in next-generation eAxles.

“With the New eAxle project we are focusing on novel design configurations just as much as our materials, asking how we can provide manufacturers with validated efficiency improvements and increased design flexibility,” says Hendrik De Keyser, chief innovation and technology officer, Vyncolit NV (Ghent, Belgium). “Our materials, combined with the new design options developed, really do deliver a powerful one-stop solution.”

Related Content

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

-

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.