Survey results indicate continuing supply chain concerns

A recent survey conducted by CompositesWorld and Gardner Intelligence of composites fabricators illuminates supply shortage, lead time and workforce issues.

Photo Credit: Getty Images

As part of CompositesWorld’s efforts to monitor and report on ongoing composites supply chain issues, CW and Gardner Intelligence have launched a series of surveys over the past year to learn more about what composites fabricators are experiencing. The first and second survey results were reported in May and October 2021.

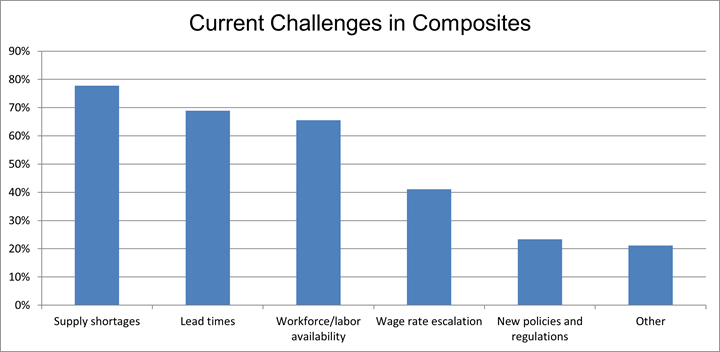

The latest survey, which had 101 respondents, indicated that the most prominent challenges in the composites industry over the past few months are supply shortages, lead times and workforce/labor availability. Compared to the fall 2021 survey, supply shortages rose in the current results as the leading challenge in the composites industry by more than 20%.

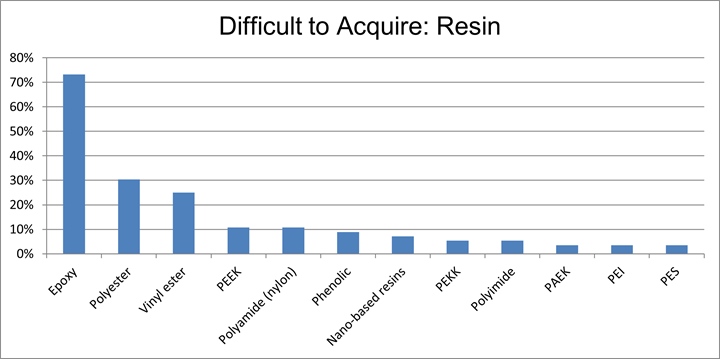

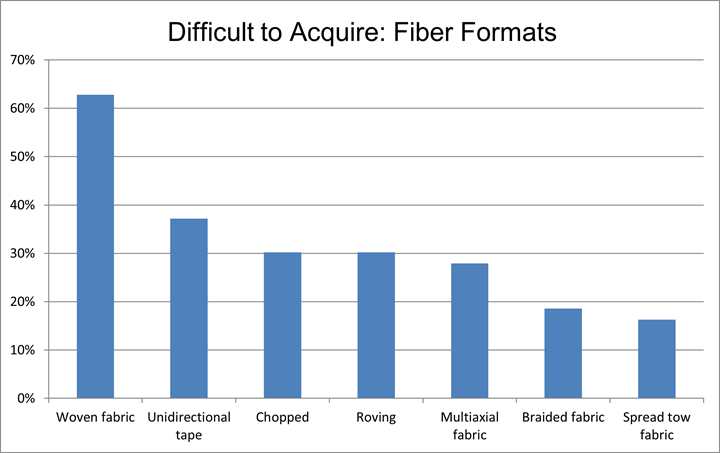

Source: Gardner Intelligence

Among resins, epoxy remains the most difficult to acquire, based on survey respondents. Carbon and glass fiber — particularly woven fabrics — as well as foam core are also still considered difficult to acquire.

Facilities continue to report seeking alternative suppliers, and needing to communicate with customers about increased lead times or other related issues.

In addition, in CW’s most recent Business Index column, Gardner Intelligence director of market research Jan Schafer reports that the Gardner Business Index for Composites Fabricating (which measures month-to-month changes in activity at manufacturing facilities, produced by information provided by fabricators) has expanded each month of 2022 so far. Schafer notes that production activity levels are rising, but are constrained by continuing supplier delivery and employment issues.

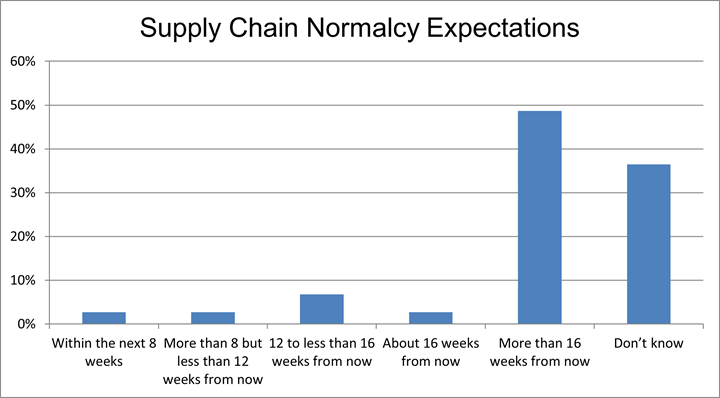

When will the supply chain situation improve? Almost half of survey respondents answered that they expect the situation to return to normal “more than 16 weeks from now.” Notably, more than one third of respondents to this question answered that they “do not know,” indicating continuing uncertainty.

Fifty-three percent of survey respondents report to be at least 80% confident that the industry will be able to bounce back and meet market needs five years from now. This is a decrease from 61% of respondents in the fall. Workforce availability is the top listed challenge to the industry five years from now, followed by supply chain issues.

Aerospace and automotive continue to be perceived as the end markets that will drive composites growth in the coming years; however, in the most recent survey, energy storage and building/construction gained more confidence from respondents as well.

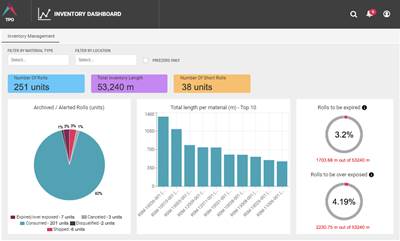

What solutions will help the situation? CW senior editor Ginger Gardiner recently interviewed Avner Ben-Bassat, president and CEO of Plataine (Waltham, Mass., U.S. and Petach Tikva, Israel), to discuss how the company’s connected suite of software for tracking materials, machines, tools and production scheduling was being used to overcome supply chain issues at composites manufacturers.

In this interview, Ben-Bassat noted, “We see that most Tier suppliers in aerospace are ramping up production volumes, meanwhile supply chain disruptions continue. And companies are also facing hiring challenges. Many companies say they don’t have the number of employees they need with the desired level of skill and experience they would like. We are seeing companies face long lead times and materials shortages, which can cause them to slow or stop production until they can get what they need.”

What are you seeing at your facility? Or what solutions are you seeing that are helping the situation? We’d love to hear from you — feel free to reach out to editor-in-chief Jeff Sloan at jsloan@gardnerweb.com or any of CW’s editors.

Read Next

Resin shortages continue to affect composites supply chain

Power outages caused by mid-February’s U.S. winter storms led to immediate shortages from Gulf Coast petrochemical companies. Fabricators continue to report shortages.

Read MoreCW survey reveals ongoing supply chain struggles

A recent survey with Gardner Intelligence underscores supply chain issues and uncertainties reported by fabricators — with a bit of hope for future growth areas.

Read MoreComposites supply chain and production disruptions – how can AI and digitalization help?

Digitizing and creating the factory of the future is a journey, but it has the potential to help composites manufacturers address real-life disruptions and enable fast replanning of production operations for increased flexibility and enterprise-level performance.

Read More

.jpg;width=70;height=70;mode=crop)