Teijin Aramid begins second phase of production capacity expansion

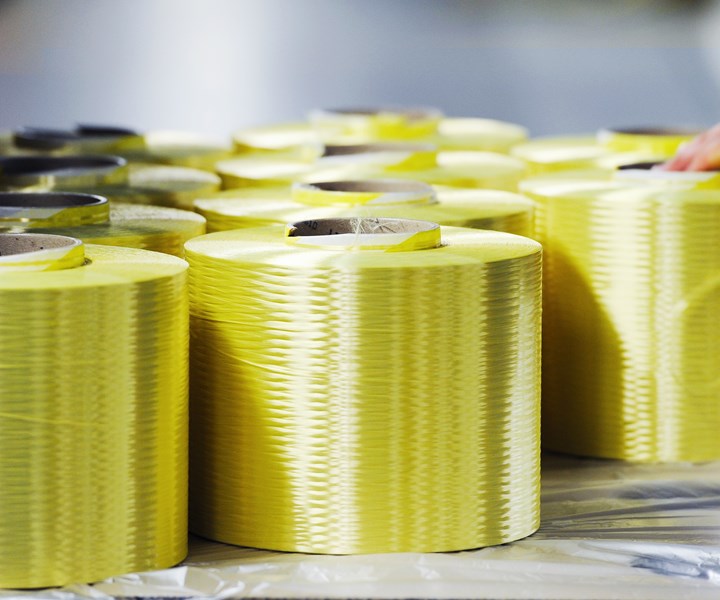

The manufacturer of Twaron aramid fiber aims to meet market demands and reinforce its position as a leader of sustainable solutions.

Source | Teijin Aramid

Teijin Aramid (Arnhem, Netherlands) is moving into the second phase of its goal toward a more than 25% production capacity increase for Twaron aramid fiber. As announced at the end of 2017, the company plans to increase its capacity over five years, and its first step was to “de-bottleneck” its production process. Now, the company says it moves into the investment phase.

Teijin Aramid, which supplies aramid fiber for markets ranging from air cargo containers to heat-resistant clothing, aims to reinforce its position as market leader and finalize capacity increase by 2022.

Teijin says the capacity increase will be used as an opportunity to invest in new technologies that reduce CO2 emissions, enabling it to lead the industry toward a more sustainable workflow. The company says that Twaron products are in high demand due to their light weight, durability and strength, features that Teijin Aramid says also increase the products’ sustainability.

Source | Teijin Aramid

The capacity increase will take place in two Teijin Aramid factories located in the Netherlands, at Delfzijl and Emmen. Delfzijl is the production site for monomers and polymers, and the plant in Emmen is used for spinning. The increase is expected to result in several dozen new jobs in the region.

“Twaron is an incredibly versatile product. It allows us to enable innovation ranging from car tires to space crafts. As the industry leader, we continue to invest in production developments to ensure innovators in a range of industries can continue to push boundaries,” says Gert Frederiks, CEO and president of Teijin Aramid.

“At the same time, we want to push our own boundaries, and use this opportunity to modernize our own production sites with a sustainable approach,” Frederiks adds. “Our end goal is to have a sustainable and circular aramid supply chain. On the one hand, this takes shape by us being more energy-efficient, being part of the energy transition movement and using increasingly green raw materials. On the other hand, we continue to provide our customers with sustainable solutions by offering Twaron.”

Related Content

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

.jpg;width=70;height=70;mode=crop)