Teijin aramid, carbon fibers used for museum façade panels

The new wing of the Stedelijk Museum Amsterdam is the first and largest composite building constructed from Teijin’s Twaron and Tenax fibers.

Source | Teijin

The Teijin Group (Tokyo, Japan) announced that its Twaron para-aramid fiber and Tenax carbon fiber were used to build 185 composite panels for the façade and canopy of a new wing of the Stedelijk Museum Amsterdam (Amsterdam, Netherlands). Measuring 100 meters by 25 meters, it is the world’s first and largest-scale composite building using Twaron and Tenax, Teijin says.

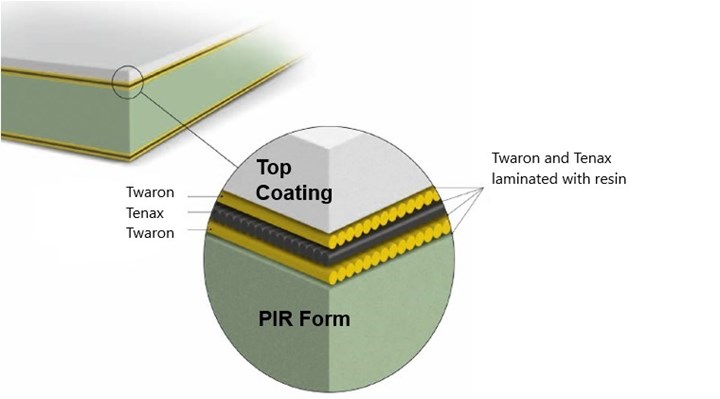

The new wing of the museum is known as the “bathtub” due to its distinctive shape. Twaron para-aramid fiber produced by Netherlands-based Teijin Aramid B.V. and Tenax carbon fiber produced by Teijin Carbon Europe GmbH in Germany were combined with vinyl ester resin in composite laminates, forming the outer skins of a composite sandwich construction with a core of PIR foam. Twaron and Tenax fibers are said to contract as temperature rises, unlike expanding resins, reportedly ensuring minimal thermal expansion of the panels while offering structural stability.

Source | Teijin

The Teijin Group has been sponsoring the Stedelijk Museum Amsterdam since 2007, as a cultural initiatives based on the company’s corporate philosophy to grow and evolve in harmony with society. Teijin is sponsoring the Colorful Japan exhibition, which opens Sept. 7, to emphasize the strong bonds between Japan, Teijin and the Netherlands.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

.jpg;width=70;height=70;mode=crop)