The Native Lab adds two online live sessions to self-paced Composite Materials course

The course, taught by Managing Composites COO, Eneko Angulo, will have two online live sessions taking place in September 2022 for students and professionals interested in learning more about composite materials, processes and design

To improve and consolidate the learning process in composites, The Native Lab (TNL, Madrid, Spain), Managing Composites’ training division, has decided to add two online live sessions to its self-paced “Composite Materials” training course.

“We have realized that self-paced courses adapt very well to different time schedules students might have. Still, having a direct interaction with the instructors is something our students value,” Tommaso Muellejans says, responsible for TNL. “The idea is to launch the sessions in September, giving those who have recently joined time during the summer to go through the materials in order to make the most out of the live sessions. Of course, both sessions will be recorded in case students cannot participate live.”

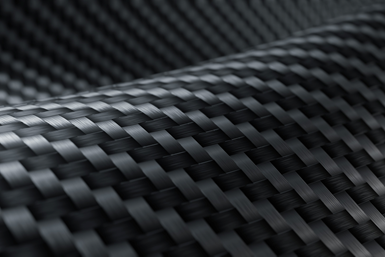

The course consists of three main blocks. The first block discusses composite materials in detail, from understanding the different types of fibers (carbon, glass, aramid, polymeric and natural fibers), matrices (with a focus on thermosets) and fabrics, to posing different scenarios in which they function.

Once the materials have been understood, the course looks at various manufacturing technologies. Each process is clearly illustrated, and the application for each clearly defined. In total, nine technologies are explained, including:

- Wet Layup

- Prepreg

- Prepreg compression molding (PCM)

- SMC/BMC

- Resin Infusion

- Resin transfer molding (RTM)

- Filament Winding

- Braiding

- Pultrusion.

The third block centers around composite part design. The entire process is outlined, including concept design, manufacturing process selection, part design, joints, layup, tooling, curing, post-processing and design for manufacturing.

Eneko Angulo, now chief operations officer (COO) of Managing Composites, is the primary trainer of the course. Previously, he was station leader at Koenigsegg Automotive AB (Ängelholm, Sweden), manufacturing carbon fiber monocoques and body panels. Later on he became SQA principal at McLaren Automotive (Woking, U.K.), responsible for more than 300 components in different technologies and more than 10 models.

Once the course has been completed, a certificate of successful completion will be granted as well as access to an ever-growing alumni network and special discounts.

The price fee is set at €269 ($270) in a one-off payment. However, TNL says there is the option to pay for the course in three installments of €99. If you are a student, you can also contact The Native Lab at info@thenativelab.com, for special discounts.

Related Content

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

-

New online training course targets prepreg basics

JEC World 2024: Composites Expert highlights how its E-Learning Composites Academy platform supports flexible industry learning with new courses developed with Stelia Aerospace North America.

-

Toray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.