ThermHex, EconCore invest in automated production for PP honeycomb sandwich, recycled PET products

Targeting recycled and high-performance thermoplastic options, automated R&D lines increase volume and speed for honeycomb, sandwich panel and finished part production.

Share

Read Next

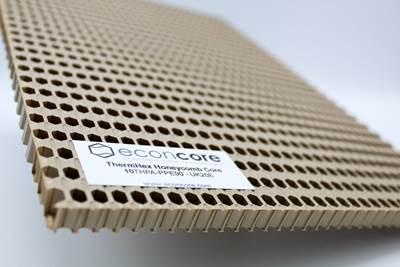

ThermHex Organosandwich panel, consisting of a polypropylene (PP) core and glass fiber skins. Photo Credit, all images: ThermHex

In February, thermoplastic honeycomb core producer ThermHex Waben GmbH (Halle, Germany), a licensee of EconCore (Leuven, Belgium), announced a €1 million capital increase and plans for process optimization and production expansion; in June, the company announced 12% growth in turnover over the past business year, as well as increased efforts toward quality certification.

ThermHex credits much of last year’s growth to the success of its Organosandwich semi-finished product, launched in 2019, which combines a polypropylene (PP) honeycomb core with glass fiber/PP skins. ThermHex’s Organosandwich panels are currently used by customers in the automotive industry, for applications such as the trunk floor of the 2020 Hyundai Creta. According to ThermHex, advantages of Organosandwich include high stiffness and strength, reduced weight and costs, reduced raw material usage, recyclability, short cycle times and the ability to use with injection molding. The company’s PP honeycomb cores are also used in vehicle roofs for Volkswagen and Ford, motorhome components, swimming pools and doors.

ThermHex’s polypropylene honeycomb core is sandwiched between glass mat thermoplastic (GMT) skins for the trunk floor of the 2020 Hyundai Creta. The floor panels are manufactured in a one-step compression molding process and include a finished edge closure and hinge.

The company is now working with the Fraunhofer Institute for Microstructure of Materials and Systems (Fraunhofer IMWS, Halle) on technology for production of hybrid sandwich components based on Organosandwich semi-finished products via forming and injection molding. According to ThermHex, the technology will enable mass production of functionalized parts with very short cycle times.

According to Mona Boche-Würfel, marketing and communications manager at ThermHex, the company is targeting sales of 1 million kilograms of PP honeycomb cores and Organosandwich this year, and yearly growth of 10-20% over the next few years.

This finished demonstrator panel was built using ThermHex and Fraunhofer IMWS’ automated production process.

Additional R&D projects for ThermHex include work funded by BMWi to develop honeycomb cores specific to aerospace applications, production of hierarchical sandwich honeycomb cores for higher load-bearing applications and development with automotive partners Daimler Truck AG (Stuttgart, Germany) and Elring Klinger (Stuttgart) of a hybrid sandwich material consisting of PP honeycomb core and a metallic outer layer. ThermHex says it is also working with AZL Aachen (Germany) on the development of a production line for injection molded sandwich panels.

Recycled PET and high-performance thermoplastic honeycombs

In addition, ThermHex’s parent company, EconCore, has also recently invested in large-scale production line development. The company says it has been seeing increased market demand for more sustainable materials and a shift in focus toward thermoplastic solutions for high-end aerospace and automotive applications.

The thermoplastic honeycomb cores that EconCore and its licensees produce are already said to be recyclable, and in the case of ThermHex, produced with green power, leading to reduced carbon emissions. “Lightweighting, strength, stiffness, resistance to chemicals and moisture: These are properties that are needed more today than ever. Together with our customers, we develop new ideas for old and new applications that drive growth while reducing CO2 emissions,” says Dr. Jochen Pflug, CEO of ThermHex.

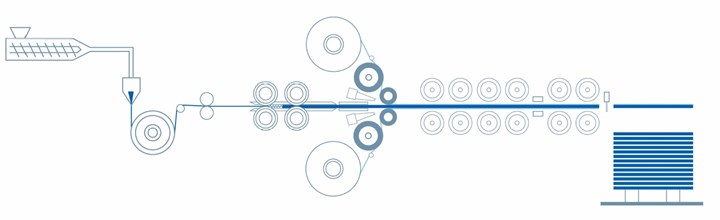

An illustration of EconCore’s automated, continuous production process, which will be used to produce rPET and HPT materials as well as ThermHex’s Organosandwich products. The continuous production line enables core and skins to be layered via an automated assembly line (pictured), which is followed by infrared (IR) preheating, transfer into a mold for forming or injection molding and then demolding.

In an effort to increase its sustainability goals further, EconCore is progressing its technology for producing recycled PET (rPET) and high-performance thermoplastic (HPT) honeycombs, focusing similarly on cost-efficient and continuous production of sandwich panels for each of these technologies. Currently, the company is producing rPET at a prototype- or lab-scale, with plans to produce the material commercially by the end of 2022.

EconCore’s current technology processes PP granulates to produce an easily recyclable core product. The next generation of this technology will process rPET flakes for an even greener solution, while still exhibiting high mechanical properties and high temperature stability.

EconCore sees increased opportunities on the horizon for rPET in the automotive market in particular, and says that the use of rPET honeycomb cores provides a sustainable solution with good life cycle assessment and a low carbon footprint.

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreRead Next

EconCore thermoplastic honeycomb cores deliver high-heat performance, facilitates recyclability

Honeycomb cores incorporate Sabic NORYL GTX resin for improved dimensional stability, lower water absorption and demonstration of thermoset composite skin compatibility.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)