EconCore thermoplastic honeycomb cores deliver high-heat performance, facilitates recyclability

Honeycomb cores incorporate Sabic NORYL GTX resin for improved dimensional stability, lower water absorption and demonstration of thermoset composite skin compatibility.

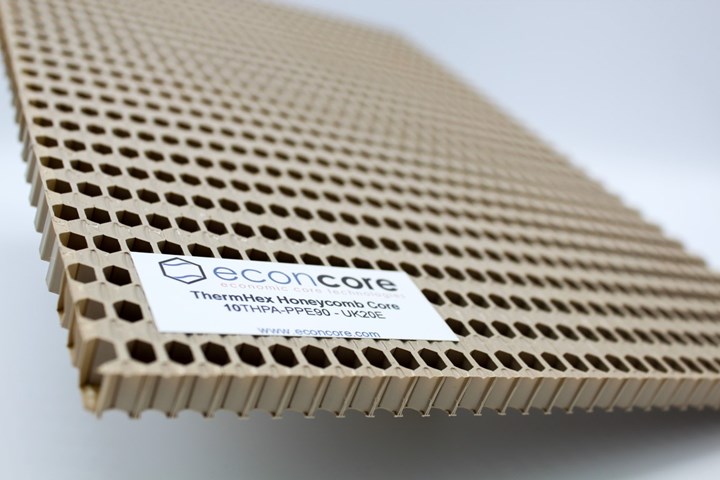

Photo Credit: EconCore

EconCore (Leuven, Belgium) has developed new honeycomb cores for laminated sandwich panels made with Sabic’s (Riyadh, Saudi Arabia) NORYL GTX resin, a polyphenylene ether (PPE) blend, and EconCore’s proprietary technology. The honeycomb core reportedly presents higher heat performance, better dimensional stability and lower water absorption compared to honeycomb structures made with traditional thermoplastics, such as nylon.

Sabic’s NORYL GTX resin aids in the core’s high heat resistance during processing up to 240°C (465°F), as well as its lower water absorption and lower density properties for reduced part weight. The resin system is said to also offer optimized impact performance and stiffness across a wide temperature range, and is offered in conductive grades that may be used in powder-coated automotive body panels.

With these properties, EconCore says the novel core material is ideal for demanding applications such as certain automotive, e-mobility and photovoltaic components. Furthermore, combining this new honeycomb core with thermoplastic composite skins to produce an all-thermoplastic sandwich panel can facilitate recycling.

According to EconCore, thermoplastic honeycomb structures offer many benefits, such as delivering a high performance-to-weight ratio, efficient energy absorption under impact, high rigidity and reduced mass. Furthermore, EconCore says sandwich panels made exclusively with thermoplastics can be efficiently processed into finished parts with complex geometries using compression molding processes, which can help reduce cycle times.

Because of the honeycomb core’s high performance, EconCore notes that the cores may also demonstrate good compatibility with thermoset composite skins. Because the honeycomb exhibits high load-bearing capacity even at temperatures up to 180°C, it may be a good candidate for lamination with thermoset prepregs in processing environments where high curing temperatures are typically applied. The honeycomb can also potentially be used for applications where sandwich panels must deliver high performance at elevated temperatures.

EconCore honeycombs are produced from a single continuous thermoplastic sheet using the company’s patented technology. The material is extruded and in-line formed into the honeycomb structure without the need for secondary operations. Specifically, this involves a sequence of extrusion and thermoforming steps to transform the extruded film into a half-hexagonal web that is directly folded into a thermoplastic honeycomb structure. The continuous process reportedly minimizes production costs and enables for the integration of the skin lamination step in-line with the honeycomb core production.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.