Toray Advanced Composites leads research consortium for LH2 composite tank developments

Dutch industries, institutes join Toray Advanced Composites for the manufacture of a civil aviation-focused lightweight composite tank which can withstand very low temperatures.

Share

Read Next

Toray Advanced Composites (TAC, Nijverdal, The Netherlands), together with partners from industry and academia, has been awarded funding from the Dutch Ministry of Economic Affairs and Climate Policy’s Research and Development for Mobility project for the development of a long-life, fully composite liquid hydrogen (LH2) tank for civil aviation.

Hydrogen has been identified by the European Commission (EC) as a key priority to achieve the European Green Deal for a sustainable economy. By converting the construction of the hydrogen tank from existing metallic solutions to composites, TAC says the LH2 composite tank will achieve weight savings that enable the advancement of LH2 as a sustainable fuel source for civil aviation. This will lower the carbon footprint of air travel and increase and extend the flight range of aircraft fleet by reducing construction weight and cost.

The cross-sector research undertaken as part of this program aims to result in a lightweight composite tank that can withstand a very low-temperature of LH2, -253°C. The project will focus on both composite tank construction, digital design strategies and production technologies.

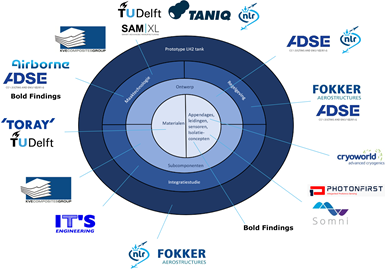

The consortium comprises of 13 partners across academia and industry: Aircraft Development and Systems Engineering (ADSE) Airborne, Bold Findings, Cryoworld, GKN Aerospace’s Fokker business, IT’S Engineering, KVE, NLR, PhotonFirst Technologies, Somni Solutions, TANIQ and Technical University Delft, together with SAM|XL.

“We are delighted to have been granted this funding. By joining together the best of Dutch industries and institutes in a unique consortium, we will contribute to the acceleration of hydrogen technology into aerospace as a sustainable fuel source for the future,” notes Frank Meurs, managing director, TAC. “This project underlines the commitment across the supply chain to drive forward sustainable propulsion technologies and is conducted in full alignment with the major aircraft and engine manufacturers.”

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.