EU launches Clean Aviation partnership, targeting 75% of civil fleet replaced for zero emissions by 2050

Clean Aviation carries forward from Clean Sky to develop disruptive new technologies, flight demonstrated by 2029 for aircraft into service by 2035 and aviation climate neutrality by 2050.

The Clean Aviation Joint Undertaking (JU) will advance the successes from Clean Sky and Clean Sky 2 as it enables zero emissions in aviation. Photo Credit: Clean Aviation, Clean-Aviation.eu

The Clean Aviation Joint Undertaking was launched on November 30, 2021. Its goal is climate-neutral aviation with zero emissions by 2050. To do that, next-generation aircraft will be required to enter into service by 2035. This ensures that a sufficient portion of global commercial airliners will be operating as zero-emissions aircraft. In fact, in order to deliver the required emissions reductions for 2050 climate neutrality, 75% of the global civil fleet will have to be replaced. “Rolling out such aircraft in 2045 or later simply won’t achieve what is necessary to stay below 1.5ºC in temperature rise,” says Axel Krein, executive director of the Clean Aviation Joint Undertaking, and previously executive director of Clean Sky 2.

Even while Clean Sky 2 projects are being completed until 2024, the first Clean Aviation call for proposals (CFP) will be issued by March 2022. The process to establish the European Partnership for Clean Aviation was begun in 2020. After collecting industry and member nation input, the resulting Strategic Research and Innovation Agenda (SRIA) has been finalized and will be approved by Dec. 16.

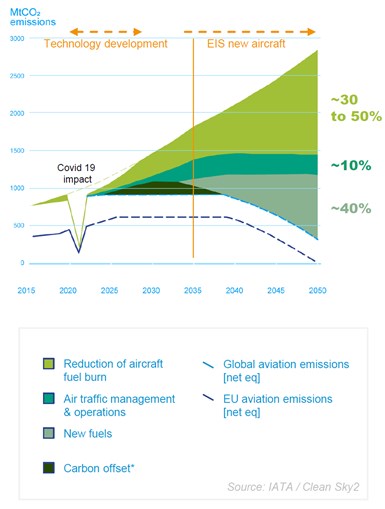

EU 1.5°C Scenario and Roadmap for EU Aviation shows metric tonnes of CO2 emissions (vertical axis) graphed versus time (horizontal axis). Photo Credit: Clean Aviation press briefing, Dec. 1, 2021

Road map for EU aviation

Clean Aviation, says Krein, is targeting aircraft with flights of 4,000 kilometers and less because this covers two-thirds of the aviation industry’s carbon emissions. The disruptive new technologies that will be developed within the Clean Aviation JU will reduce greenhouse gas (GHG) emissions by 30-50%, compared to 2020. This can be seen in the graph at right.

“We will finish these technologies by 2027-2029 and flight demonstrate by 2030 in order to have next-generation aircraft ready for entry into service (EIS) by 2035,” says Krein.

Clean Aviation comprises three key technology thrusts, each with targeted R&I (research and innovation) and demonstration efforts:

- Hybrid electric regional aircraft utilizing distributed propulsion coupled with highly efficient aircraft configuration.

- Ultra-efficient short and short-medium range aircraft featuring advanced aircraft configuration and ultra-efficient gas turbine engines with ultra-high bypass (possibly open rotor).

- Hydrogen-powered aircraft to exploit the potential for a zero-carbon fuel, particularly liquid hydrogen.

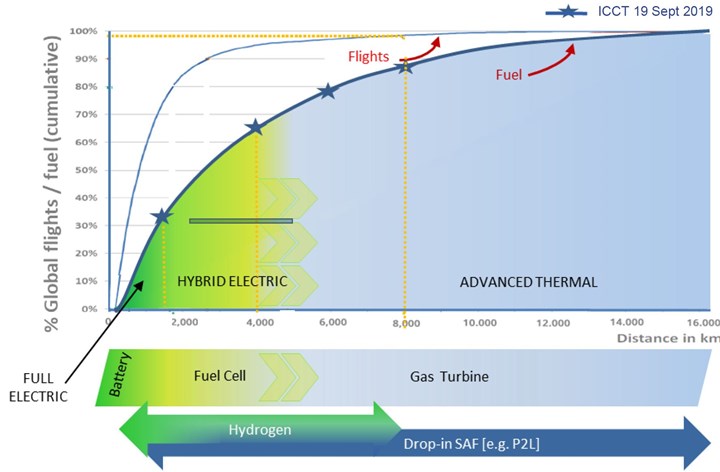

The graph below shows how these key technology thrusts fit into the Clean Aviation framework targeting flights less than 4,000 kilometers. Krein believes these new technologies will be offered to the airlines in the 2027-2029 timeline, “and we will see then the results of our work.”

To reach zero emissions by 2050, the Clean Aviation framework is targeting aircraft with flights less than 4,000 kilometers, and innovation/demonstration goals within the key technology thrusts of hybrid electric propulsion, hydrogen propulsion and ultra-efficient aircraft and engine configurations. Photo Credit: DLR/Sabre, Clean Aviation press briefing on Dec. 1, 2021

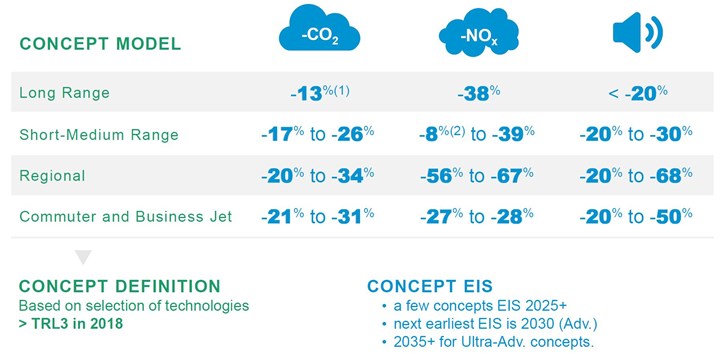

“A big focus for this framework is impact,” says Krein. “In other words, what does each technology achieve, how can it be applied and what impact will it have toward the 2050 goal?” To answer these questions, Clean Aviation will establish an Impact Monitoring Framework (IMF) to evaluate the progress of each project toward overall program milestones and objectives. The new technologies and architectures developed will be harmonized and integrated through aircraft concepts and compared with relevant reference state-of-the-art aircraft, engines and systems as of 2020. The IMF will collect and assimilate research results and their potential benefits — from technology development through integration studies and up to large-scale demonstrations — with the goal to summarize and visualize program impacts versus aviation’s trajectory towards climate neutrality.

Skip-a-generation technology leap

Clean Aviation will build on the successful results from Clean Sky and Clean Sky 2, says Krein, but it will also demand a significant leap in technology. “This is our moonshot,” he emphasizes, and it will require a wide range of development — pushing the envelope in all traditional aeronautical disciplines but also advancing in non-traditional areas including:

- Electrical power generation and distribution (high voltage; >>1 megawatt)

- Thermal management

- Energy management systems enabling hybridization

- LH2 storage and fuel systems

- Distributed systems and increased autonomy

In addition, Krein stressed that novel manufacturing systems will need to be developed to enable the high rate of production necessary to replace 75% of the global fleet by 2050. Innovation in certification will also be key, said Krein, and will include new developments in simulation and digital twin. “EASA [European Union Aviation Safety Agency] is a key partner,” says Krein, “and will be working with us toward certification of new aircraft by 2034.” The final area of emphasis for this technology leap includes improved life-cycle analysis (LCA) performance and recyclability. But how much will this play a role in the Clean Aviation program’s objectives and impact analysis? “We cannot have technology that is not recyclable,” says Krein. “This is also part of manufacturability. Just producing aircraft with reduced emissions is not enough. They must also be manufactured at high rates at an affordable cost and they must be sustainable.” He added that state-of-the-art aircraft technology today includes recyclability.

This summary of the Clean Sky 2 Technology Evaluator, and its first assessment of program results at a mission level, shows good progress toward CO2, NOx and sound reduction goals. Photo Credit: Clean Sky 2, Clean Aviation

Even with manufacturability and recyclability addressed, how will it be possible to replace 75% of the global fleet without Boeing equally committed? “Of course, aviation is global,” says Krein, “but we are an EU entity so that is our focus. I think it is just a matter of time. Boeing has already moved to using SAF [sustainable aviation fuel] but this does not offer enough energy efficiency. Airbus and the EU aviation ecosystem is pursuing the hydrogen path, but so are many companies in the U.S.” He also noted that the U.S. is starting to catch up to the EU in developing hydrogen, thanks to the recent funding pushed by the Biden administration. “There is real potential for both public and private sector funding in the U.S. to not only catch up but overtake the EU,” Krein added.

Rendering of green regional aircraft for Clean Sky 2 demonstrator projects led by Leonardo (Rome, Italy). Photo Credit: Clean Sky 2 REG IADP consortium, Leonardo

Airbus rendering for ZEROe turbofan aircraft using hydrogen fuel. Photo Credit: Airbus

German Aerospace Center (DLR) rendering of novel aircraft for emission-free, electric flight. Photo Credit: DLR

EU funding and intelligent collaboration

The Clean Aviation JU is one of 10 new European partnerships to accelerate the transition to a green, climate-neutral and digital Europe, which will also make the European industry more resilient and competitive. Out of the €10 billion funding for these 10 partnerships, Clean Aviation will receive €1.7 billion from the European Commission and another €2.5 billion from private sector funding.

“We will need to be very intelligent with this investment,” says Krein, “as we calculated that €12 billion will be needed for the global aviation industry to reach zero emissions by 2050. Thus, our innovation architecture must be intelligent so that within the EU, we are not duplicating effort.”

One of his key tasks, for example, will be to develop the necessary cooperation with the Fuel Cell and Hydrogen Joint Undertaking (FCH-JU), as well as with national and regional aviation and technology R&D programs within EU member states. “There are complementary funds and goals within various countries and regions,” says Krein, “but we must all work together and efficiently, thus it’s imperative to develop a common roadmap.”

Clean Aviation JU is building an EU-wide innovation architecture and supply chain — from academia and research organizations, to SMEs and large industrial enterprises. “Our goal of 30-50% extra energy efficiency is possible and liquid hydrogen is by far the most promising energy carrier,” says Krein. The first Clean Aviation forum will be held as a hybrid online and in-person event on March 22-23, 2022 in Brussels, Belgium.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More