TPRC announces press forming dataset publication

Recent research by academia aimed to validate composite forming simulations for press forming UD thermoplastic composite laminates.

PhD researcher Dennis Brands, part of the University of Twente (UT, Enschede, Netherlands) ThermoPlastic Composites Research Center (TPRC), recently published a dataset with press forming results for unidirectional (UD) thermoplastic composite laminates.

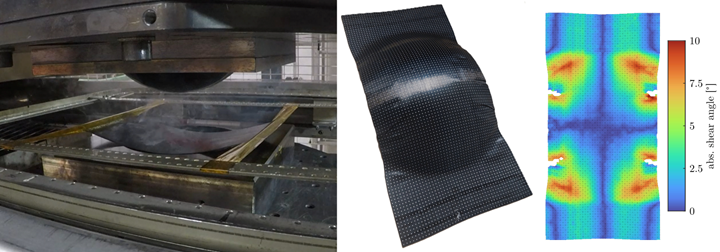

The dataset was designed for the validation of composite forming simulations, featuring high-resolution, in-plane deformation measurements and clear wrinkling observations. An accompanying dataset description article was published in the journal Data in Brief, which provides all the relevant details of the experimental and analysis methodologies used. The dataset encourages discussion on the material behavior during press forming and offers the potential to benchmark numerical simulations.

According to the accompanying article abstract, “Truncated hemisphere parts were press formed with two commercially available unidirectional thermoplastic composite materials, namely Toray TC1225 and Solvay APC. The width and layup of the laminates were varied to influence the wrinkling severity, to trigger various deformation mechanisms and to influence the amount of in-plane deformation. A total of eight layup/width combinations were selected and formed in triplicate for both materials, resulting in the analysis of 48 parts in total.”

This dataset and description was published with open access as part of TPRC’s “Press forming without defects” (PERFECT) project, led by close collaboration with Václav Vomáčko from the Technical University of Liberec (Czechia) and together with Sebastiaan Wijskamp, Wouter Grouve and the Production Technology research group of Remko Akkerman at the University of Twente. The NWO (Nederlandse organisatie voor Wetenschappelijk Onderzoek) provided project funding.

Read about the dataset here.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.