Two major automotive OEM contracts secured for EconCore honeycomb core technology

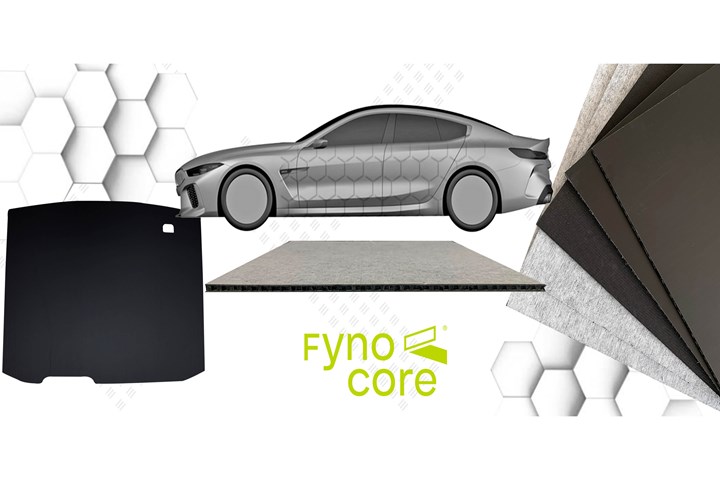

Mexican manufacturer Fynotej will supply OEMs with the lightweight and sustainable Fynocore — licensed under EconCore — for automotive application.

Photo Credit: EconCore

It was announced that nonwoven specialist, Fynotej (Buenavista, Mexico) has secured major OEM contracts for what is said to be two of the largest automotive manufacturers for the supply of EconCore’s (Leuven, Belgium) thermoplastic honeycomb technology.

Per the two contracts, Fynotej will supply 180,000 square meters of trunk load floors annually using Fynocore, the brand name for Fynotej’s continuous honeycomb panel technology licensed from EconCore. One contract is for a new, as-yet launched project and the other is for a current platform already in production.

According to Fynotej, Fynocore provides many advantages over existing, conventional solutions, such as contribution to greater fuel savings and a reduction in CO2. The product, typically made from 30% recycled content, also ensures a more sustainable and environmentally friendly product.

“The ability to continuously “extrude” honeycomb sandwich panels cost effectively, combined with the perspective to choose out of many material choices for both core and the skins, provides great optimization potential and opens up countless applications that the technology is being used for,” says Tomasz Czarnecki, COO at EconCore.

Fynotej notes that in this automotive application, the honeycomb core panel is made from polypropylene, which is reportedly lighter and better performing than conventional, more expensive solutions. Fynotej also uses a proprietary inline lamination process that can laminate panels with nonwoven automotive carpets by thermofusion without using adhesives, resulting in further savings for customers.

“We’re excited about the range of applications the honeycomb technology can be used for,” says Fynotej’s Sales Manager Fabiola Carbajal. “It is extremely versatile, as it can be tuned to fit customer’s requirements while, for the applications requiring it, the thermoplastic honeycomb panels can also be effectively compression molded to more complex geometries. We’re keen to engage with automotive OEMs and Tier 1 suppliers, ideally in the design stage, where our products can be specified from the outset. We know vehicle manufacturers, as they transition to electric and hybrid cars, see lightweighting as a critical area for development, to increase the range of these vehicles. Our products fit very well with this thinking, as well as being commercially competitive too.”

Czarnecki concludes, “What Fynotej is doing with the technology today, not just in the automotive sector, but also in packaging and construction, is a perfect demonstration of the sheer versatility of the technology. We’ll continue to support Fynotej as a licensee, by pushing the technology developments further and exchanging the know-how.”

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.