Victrex optimizes PAEK polymers for AM platform

The University of Exeter has commissioned an EOS P 810 laser sintering platform, for use with Victrex high-temperature PAEK polymers.

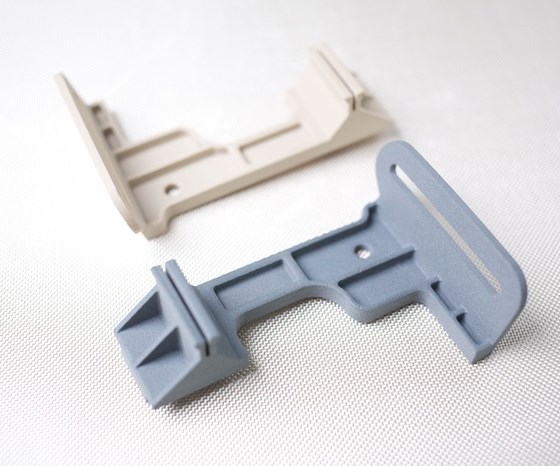

Source | Victrex

The University of Exeter’s (Exeter, U.K.) Centre for Additive Layer Manufacturing (CALM), in collaboration with Victrex (Cleveleys, U.K.), is one of the first to commission the recently launched EOS P 810 laser sintering additive manufacturing (AM) platform, for use with Victrex high-temperature polyaryletherketone (PAEK) polymers.

The goal of the partnership is to introduce next-generation Victrex PAEK polymers and composites while improving the performance of the underlying AM processes. The university says investment in the new EOS P 810 platform is expected to accelerate the commercialization of AM for high-performance parts.

“We can now further our research by utilizing the next generation of high temperature systems, the EOS P 810,” says Professor Oana Ghita, the lead of CALM at the University of Exeter. “The new equipment allows us to link the fundamental research with the commercial manufacturing process, to optimize the materials and their application, while accounting for the new thermal, optical and mechanical upgrades and providing us with accurate insights into the detailed dynamics of laser sintering.”

The EOS P 810, which has a build volume of 700 by 380 by 380 millimeters and two 70-watt lasers, is capable of printing with materials that have melting temperatures around 300°C. According to Victrex, it is suitable for the low-melting-point PAEK polymers the company has designed and optimized specifically for AM.

“This is an exciting milestone in our collaboration with the University of Exeter, which we announced in 2018, creating an effective eco-system to accelerate the commercialization of AM materials for performance parts to meet customer needs,” says Ian Smith, Victrex director of innovation.

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;width=70;height=70;mode=crop)