Virtek partners with Measurement Solutions Ltd.

The partnership will offer increased product diversity to MSL’s U.K. manufacturing customers and increase adoption of the Virtek Iris 3D system.

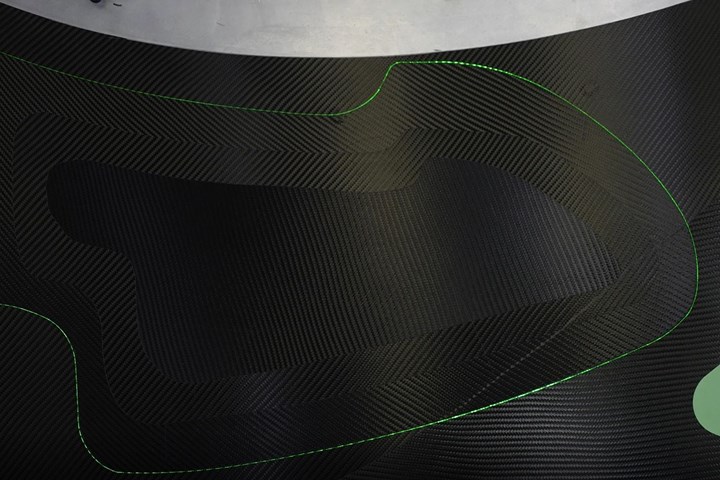

3D Ply layup projection from Virtek. Photo Credit: Virtek

Virtek Vision (Waterloo, Ontario, Canada), a producer of 3D laser-based projection systems for hand layup of fiber plies, has announced a strategic partnership with metrology equipment and design software provider Measurement Solutions Limited (MSL, Hampton, Peterborough, U.K.). The partnership offers increased product diversity to MSL’s U.K. manufacturing customers, with laser projection solutions that can help streamline production and boost productivity during the manufacturing process.

MSL says it will continue to provide customers with solutions in the fields of 3D inspection software and portable metrology solutions, such as 3D scanning and fully automated quality control. The partnership will enable MSL to increase its expansion into the digital measurement and information sectors, including automation and Industry 4.0.

As part of the company’s expansion plans, MSL will increase adoption of the Virtek Iris 3D system. According to the company, the Iris 3D differentiates itself from other technologies due to the precision of the laser-projected image generated from the product’s CAD data and enhanced by the integrated vision system. MSL says it has promoted the benefits of using reflective photogrammetry targets for super-fast data capture, multiple device positioning (leap frogging) in a shop floor environment for some time. The Iris 3D reportedly uses the same principles to increase projection envelopes, enabling larger component applications from a single hardware investment.

Andrew Tagg, managing director at MSL, says, “We have been seeking to expand the product portfolio for a number of years now, and our goal was always to select a complimentary product that does not compete with existing capabilities, or partners, but one that allows us to further develop our existing customer relationships and increase our implementations across the entire design, manufacture and inspect process. We are excited by what our new partnership will bring as we can now also support the production and build processes for composite layup, fabrication and guided assembly, projecting laser templates exponentially faster with innovative vision technology with laser projection in one system.”

Related Content

-

Broetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.